Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

Welding robots have revolutionized the manufacturing sector by offering precision, efficiency, and consistency in welding processes. Among the numerous options available, the fanuc welding robot stands out as a popular choice for various industrial applications due to its advanced technology and versatility. This type of robotic system is designed to automate welding tasks, significantly reducing human error while enhancing the quality of the final product.

The operation of a welding robot involves complex algorithms and programming that enable it to perform a range of welding techniques, such as MIG, TIG, or arc welding. When integrated into manufacturing lines, the fanuc welding robot not only improves production speed but also allows for more intricate and detailed work than traditional methods would permit. Ultimately, the introduction of welding robots into factories marks a transformative step towards smarter and more efficient manufacturing processes. As industries continue to embrace automation, understanding how these robots function is essential for optimizing their capabilities and ensuring a successful integration into existing workflows.

Robotic welding technology represents a significant advancement in manufacturing, allowing for precise, efficient, and consistent welds across a variety of materials. A welding robot is an automated machine designed to perform welding tasks by utilizing programmed movements and sophisticated sensors. According to a report from the International Federation of Robotics, the adoption of industrial robots, including welding robots, has increased dramatically, with a growth rate projected to reach 22% year-over-year through 2025. This rise underscores the industry's shift towards automation to enhance productivity and maintain quality standards.

Welding robots utilize various technologies, including arc welding, laser welding, and spot welding, to execute tasks with high precision. The integration of advanced software and artificial intelligence enables these robots to adapt to different welding conditions and materials, optimizing the welding process. A study by Deloitte highlights that incorporating robotic welding can improve operation speed by 50%, reduce error rates, and significantly lower labor costs. As manufacturers seek to streamline operations and address labor shortages, the role of welding robots in modern production lines will continue to expand, transforming traditional welding practices into more efficient automated systems.

Welding robots have revolutionized the manufacturing landscape with their efficiency and precision. At the core of these robots are essential components, which can be broadly categorized into hardware and software. The hardware component includes the robotic arm, welding power supply, and end effector, which is the tool that carries out the welding process. These elements work in tandem to perform tasks such as spot welding, arc welding, and laser welding, ensuring high repeatability and consistent quality in production.

On the software side, the robot is guided by sophisticated programming and control systems that dictate its movements and operations. This includes path planning algorithms that optimize welding trajectories and real-time feedback systems that monitor weld quality. Integration of sensory technology can also allow the robot to adjust its operations based on immediate environmental conditions or material variations.

Tips: When selecting a welding robot for your manufacturing process, consider the specific welding type and materials you'll be working with. Additionally, invest in proper training for your team to maximize the efficiency and functionality of the robotic system. Regular maintenance of both hardware and software will significantly extend the lifespan and reliability of your welding robots.

Welding robots have revolutionized the manufacturing industry by enhancing precision, productivity, and safety. Among the various types of welding robots, arc welding robots are among the most common. These robots use an electric arc to melt metals at a welding joint, allowing for the fusion of materials. Typically employed in industries like automotive and heavy machinery, arc welding robots are known for their speed and efficiency. They can handle complex welds while maintaining a consistent quality, significantly reducing human error and improving the overall output in manufacturing processes.

Spot welding robots are another essential type in the welding robotics landscape. These robots function by applying heat and pressure to join metal components at specific points, making them ideal for surface welding applications. Spot welding is frequently utilized in assembling products like car bodies, where quick and reliable joins are critical. The precision of spot welding robots allows for a faster production rate while ensuring the structural integrity of the welded components. In addition, TIG (Tungsten Inert Gas) welding robots have gained popularity for their ability to produce high-quality welds on thin materials and non-ferrous metals. These robots provide a high degree of control over the welding process, making them suitable for applications in industries such as aerospace and electronics, where fine details are paramount.

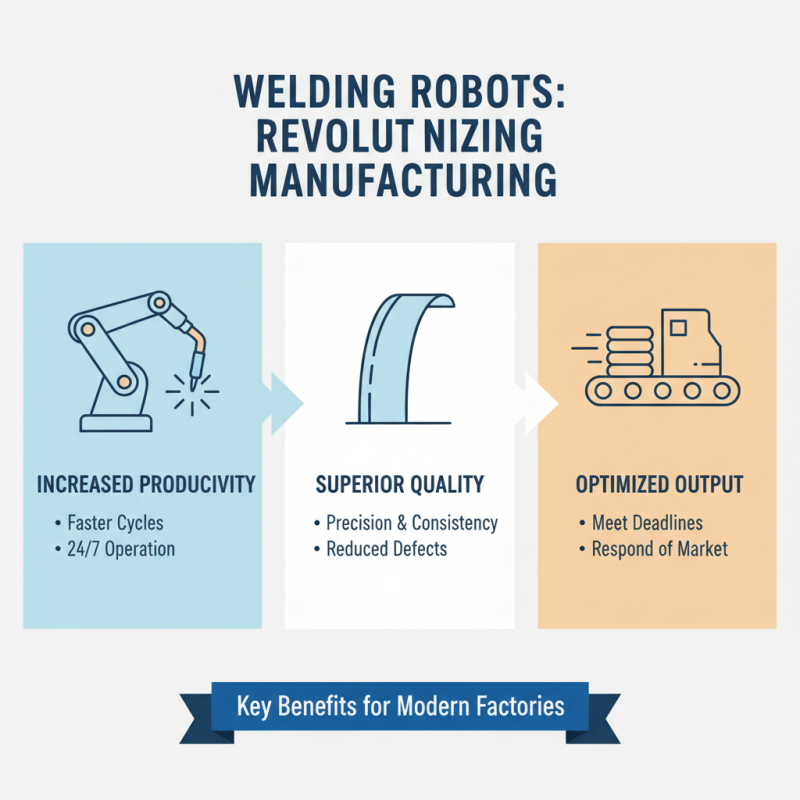

Welding robots have revolutionized the manufacturing landscape by significantly enhancing productivity and improving the overall quality of welded products. One of the primary benefits of incorporating welding robots into manufacturing processes is their ability to perform repetitive tasks with precision and consistency. Unlike human welders, robots do not experience fatigue and can operate continuously, resulting in faster production rates. This increase in efficiency allows manufacturing facilities to meet tight deadlines and respond swiftly to market demands, ultimately boosting overall output.

Moreover, the quality of welds produced by robots tends to surpass that of manual welding. Robots are programmed to follow specific parameters, ensuring uniformity in each weld. This automated approach minimizes the risk of human error, which can lead to defects and rework. Additionally, advanced robotic systems can easily adapt to different welding techniques, accommodating various materials and project specifications. As a result, manufacturers benefit from enhanced quality control, resulting in stronger and more reliable products, which can improve customer satisfaction and reduce costs related to warranty claims and repairs.

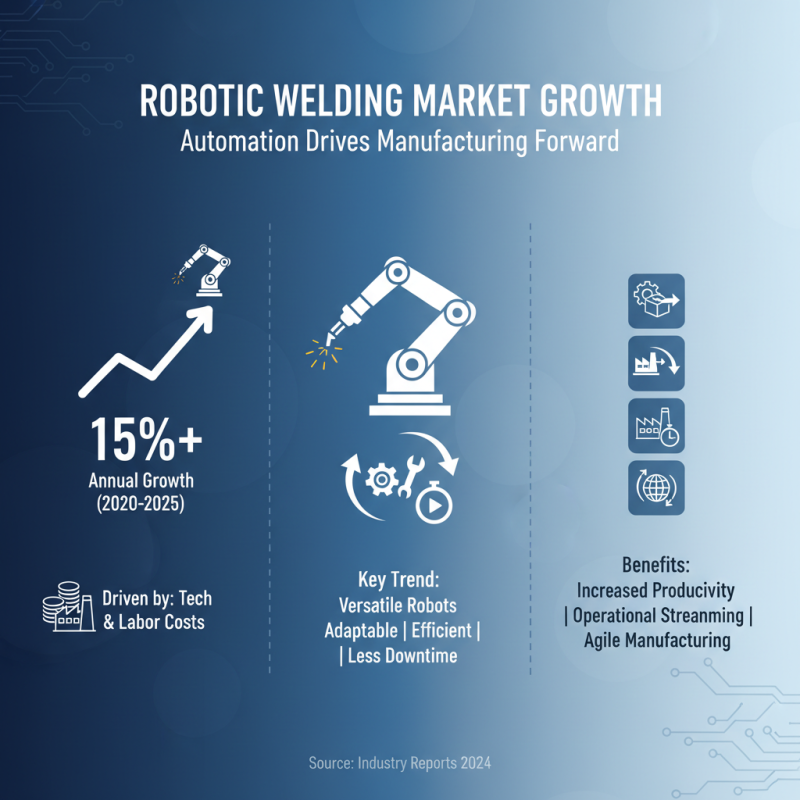

The market for robotic welding solutions has been experiencing significant growth, driven by advancements in technology and rising labor costs. Many manufacturers are investing in automation to enhance productivity and maintain competitiveness. Recent trends indicate a shift towards more versatile welding robots that can adapt to various tasks, allowing manufacturers to streamline operations and minimize downtime. This flexibility is particularly valuable in industries where production runs are shorter and need to adjust frequently to changes in demand.

When considering the implementation of robotic welding, companies should start by assessing their specific needs and processes. Understanding the types of materials to be welded and the volume of production is crucial for selecting the right equipment. Additionally, investing in training for staff to work alongside these robots can greatly improve efficiency and safety on the shop floor.

As the industry evolves, it's essential to stay informed about emerging technologies, such as artificial intelligence and machine learning, which are beginning to play a role in robotic welding. These innovations can optimize welding parameters in real-time, increasing both quality and output. Embracing these trends will position manufacturers favorably in a competitive landscape, allowing them to leverage the full potential of robotic solutions.