Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

As we move towards 2025, the landscape of manufacturing is undergoing a significant transformation, with automated welding systems at the forefront of this evolution. According to a recent industry report from MarketsandMarkets, the global automated welding market is projected to reach USD 6.17 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.72%. This growth is driven by the increasing demand for precision and efficiency in manufacturing processes, as well as the need to reduce operational costs and enhance product quality.

The integration of advanced technologies such as artificial intelligence, machine learning, and robotics into automated welding systems is revolutionizing traditional welding methods. A study by Research and Markets highlights that the adoption of these technologies not only improves the speed and accuracy of welding operations but also allows for real-time monitoring and predictive maintenance, thereby minimizing downtime. Consequently, businesses are investing heavily in these systems to gain a competitive edge and meet the rising expectations of quality and operational efficiency.

In this context, understanding the top trends in automated welding systems for 2025 is crucial for manufacturers aiming to stay relevant in an increasingly automated industry. From enhanced safety features to energy-efficient solutions, the forthcoming innovations promise to transform welding practices, streamline production processes, and ultimately pave the way for a more connected and efficient manufacturing environment.

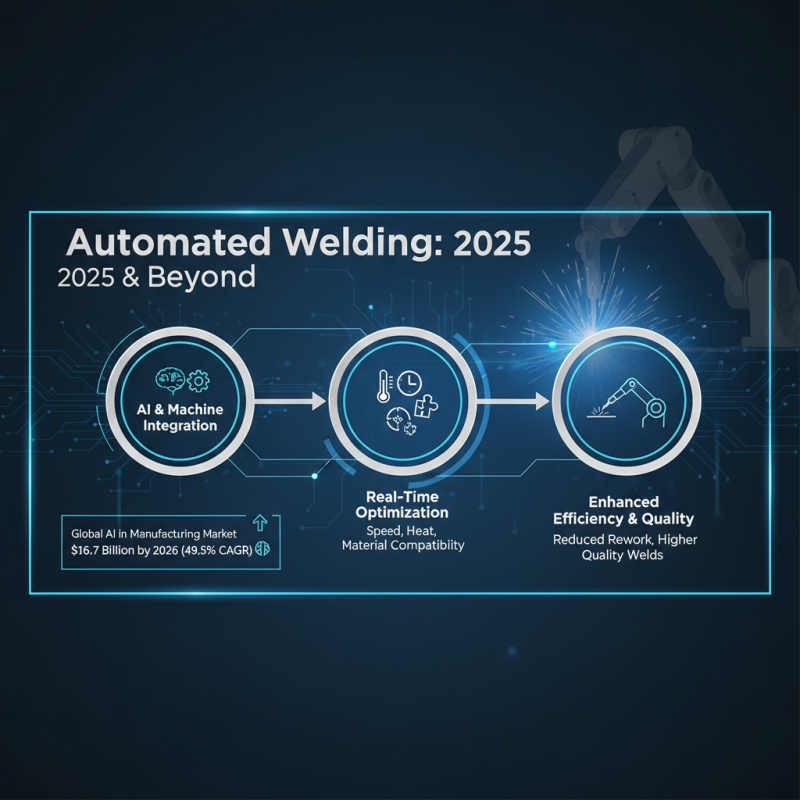

As we approach 2025, the landscape of automated welding systems is set to undergo significant transformations driven by emerging technologies that enhance efficiency. One of the key trends is the integration of artificial intelligence and machine learning into welding processes. According to a report from MarketsandMarkets, the global market for AI in manufacturing is projected to reach $16.7 billion by 2026, growing at a CAGR of 49.5%. This shift enables real-time adjustments during welding, optimizing parameters such as speed, heat input, and material compatibility, which ultimately leads to higher-quality welds and reduced rework costs.

Another noteworthy advancement is the adoption of advanced sensors and IoT technologies, which facilitate comprehensive monitoring and control over welding operations. The use of smart sensors enables predictive maintenance, allowing companies to minimize downtime and extend the lifespan of welding equipment. A report by Deloitte indicates that manufacturers implementing IoT solutions can see a productivity increase of up to 30%. Furthermore, the data collected from these connected systems can be analyzed to identify inefficiencies and further refine the welding processes, ensuring that the systems are both adaptive and intelligent in their operation.

Lastly, the rise of robotic welding systems equipped with enhanced vision technology is transforming manufacturing capabilities. These robots can interpret complex designs and adjust their processes autonomously, improving throughput in production lines. According to the International Federation of Robotics, the global stock of operational industrial robots is forecasted to reach 4 million units by 2025, highlighting a robust trend toward automation. This increased integration of robots with advanced vision systems not only streamlines production but also opens avenues for innovation in complex manufacturing processes.

The evolution of robotic welding applications is rapidly transforming various industries, offering enhancements in productivity, precision, and adaptability. With advancements in artificial intelligence and machine learning, automated welding systems are now capable of real-time adjustments based on varying parameters such as material type, thickness, and joint configuration. This adaptability allows manufacturers to streamline their processes, minimize waste, and improve the quality of welded joints, ultimately leading to higher efficiency and reduced operational costs.

Moreover, the integration of advanced sensor technology plays a critical role in modern robotic welding. These sensors enable automated systems to monitor and analyze the welding process continuously, ensuring that any anomalies are detected and corrected instantly. This not only enhances the consistency and reliability of welds but also significantly minimizes the need for extensive post-weld inspections. As industries such as automotive, aerospace, and construction increasingly adopt these cutting-edge technologies, the future of automated welding appears promising, heralding a new era of manufacturing excellence.

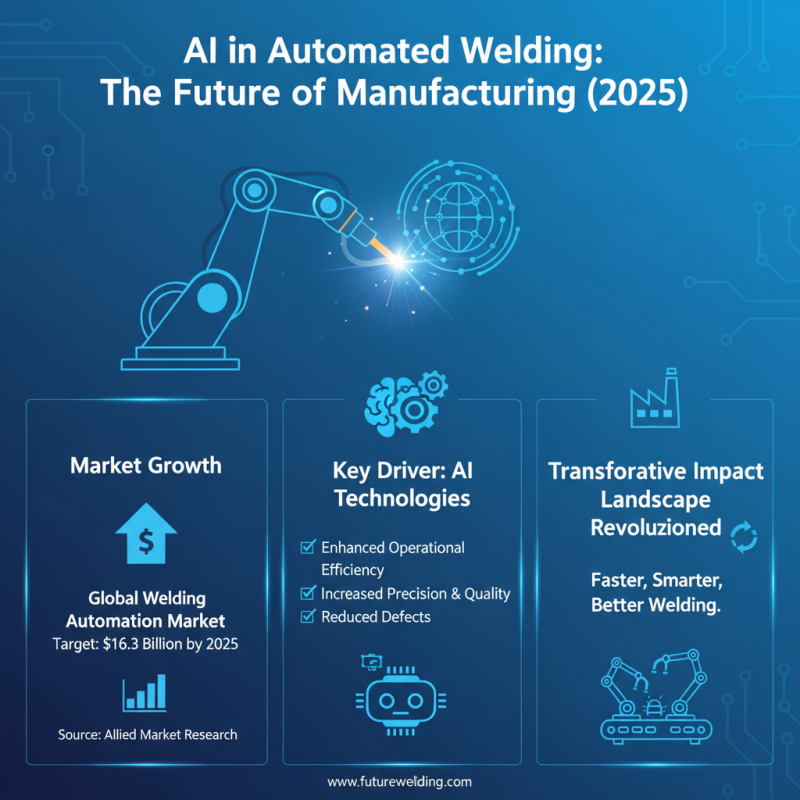

The integration of Artificial Intelligence (AI) in welding systems is rapidly transforming the manufacturing landscape, positioning itself as a key trend for automated welding in 2025. According to a report by Allied Market Research, the global welding automation market is anticipated to reach approximately $16.3 billion by 2025, driven significantly by advancements in AI technologies. These innovations not only enhance operational efficiency but also increase the precision of welding applications, reducing defects and improving overall product quality.

AI-powered welding systems utilize machine learning algorithms to analyze real-time data, enabling them to adapt to varying materials and conditions on the fly. This adaptability leads to optimized welding processes, reducing waste and energy consumption, which is vital in today’s eco-conscious manufacturing environment. A study from Market Research Future indicates that incorporating AI can improve productivity rates by up to 30%, making it an essential strategy for manufacturers aiming to stay competitive in a rapidly evolving market.

Moreover, the use of AI facilitates predictive maintenance in welding operations. By continuously monitoring equipment performance and predicting potential failures, companies can minimize downtime and extend the lifespan of their machinery. According to a report by ResearchAndMarkets, predictive maintenance applications in manufacturing could save up to $630 billion globally by 2025. The integration of AI in welding systems not only ensures higher efficiency but also transforms traditional practices, pushing the industry toward a more intelligent and sustainable future.

As industries move toward more environmentally friendly practices, the trends in automated welding systems are increasingly influenced by sustainability. Manufacturers are now prioritizing energy-efficient technologies that minimize waste and reduce the carbon footprint associated with welding processes. This shift not only helps in complying with stringent regulations but also enhances the overall efficiency and cost-effectiveness of operations. Automation is enabling companies to use less energy while achieving higher precision, thus facilitating sustainable production practices.

Tips: When considering automated welding systems, assess energy consumption metrics to choose equipment that promotes sustainability. Regular maintenance of welding machines can also improve their efficiency, reducing unnecessary energy use.

Moreover, the integration of renewable energy sources into welding operations is gaining momentum. Companies are investing in solar or wind energy to power their machines, aligning with global sustainability goals. Additionally, advancements in materials technology are leading to the development of eco-friendly welding consumables that are less harmful to the environment. This not only helps in reducing pollution but also contributes to the overall lifecycle sustainability of the products being produced.

Tips: Explore partnerships with suppliers that provide eco-friendly materials and consumables. Implementing a recycling program for welding scraps can further enhance sustainability efforts in welding operations.

The role of Industry 4.0 is pivotal in shaping the future of automated welding systems, revolutionizing the way manufacturing processes are approached. By integrating advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and machine learning, manufacturers can achieve unprecedented levels of efficiency, precision, and flexibility in their welding operations. These technologies enable real-time data collection and analysis, allowing for dynamic adjustments during the welding process, which minimizes errors and reduces waste.

Moreover, the integration of Industry 4.0 principles facilitates greater interoperability among various systems and machines. This interconnectedness not only streamlines operations but also enables predictive maintenance. As sensors installed in welding equipment monitor performance continuously, manufacturers can anticipate failures before they occur, thereby improving uptime and reducing costs. The shift towards smart factories means that automated welding systems will increasingly be part of a larger ecosystem, communicating seamlessly with other production units and contributing to a more agile and responsive manufacturing environment. This evolution is essential for companies aiming to remain competitive in an increasingly automated and digitized industrial landscape.