Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

The rapid evolution of automation in the manufacturing sector has led to a significant rise in the adoption of mobile welding robots. According to a recent report by the International Federation of Robotics (IFR), the global market for industrial robots is expected to reach $70 billion by 2025, with mobile welding robots playing a key role in this growth. These versatile machines not only enhance productivity but also improve the quality and precision of welding tasks, catering to a wide range of industries, from automotive to construction.

As businesses continue to seek ways to augment their fabrication efficiencies and meet stringent quality standards, selecting the right mobile welding robot becomes crucial. Factors such as payload capacity, mobility, and compatibility with existing systems are essential considerations. Moreover, a study by MarketsandMarkets indicates that approximately 30% of companies have reported enhanced operational flexibility and reduced labor costs since implementing mobile welding solutions. Therefore, understanding the core features and benefits of mobile welding robots will enable organizations to make informed decisions that align with their specific welding needs and operational objectives.

When selecting the best mobile welding robot for your needs, understanding your specific welding requirements and applications is crucial. Different projects may demand varying levels of precision, speed, and material compatibility. Start by evaluating the types of materials you will be working with, as certain welding robots are designed to handle specific metals or alloys. Consider the thickness and complexity of the components you will be welding, as these factors will directly influence the robot's specifications and capabilities.

Moreover, the environment in which the welding will take place plays an essential role in the decision-making process. For instance, if you'll be operating in confined spaces or challenging terrains, a more compact and maneuverable robot might be necessary. Additionally, assess the required welding processes, such as MIG, TIG, or spot welding, and ensure that the robot is equipped to perform these tasks efficiently. Understanding these parameters will not only enhance productivity but also ensure the quality and durability of your welds, making it a vital step in choosing the right mobile welding robot.

When selecting a mobile welding robot, several key features deserve careful consideration to ensure it meets your specific needs. First and foremost, the robot’s payload capacity is crucial; it should be able to handle the materials and components you typically work with. The type of welding processes supported by the robot—such as MIG, TIG, or stick welding—also significantly impacts its versatility. Understanding the suitable welding thickness and speed will help you assess if a particular robot can effectively perform your required tasks.

Another important feature is the mobility and reach of the welding robot. A well-designed mobile robot should have an efficient mobility system that allows it to navigate various job sites with ease, including uneven surfaces. Additionally, the reach of the robotic arm determines the welding area it can cover, so finding a robot with an appropriate arm length for your applications is critical. Connectivity options are also worth considering; a robot that integrates smoothly with existing systems and software can streamline operations and enhance productivity.

This bar chart illustrates the key features to consider when selecting a mobile welding robot. The categories have been chosen based on common criteria that impact performance and efficiency.

When evaluating the mobility and flexibility of welding robots, it’s crucial to consider the specific applications where these machines will be utilized. Mobility refers to how easily a robot can navigate its environment, which is particularly important in settings with varying workspace layouts. A robot that can easily move between different workstations or around obstacles enhances productivity and reduces downtime. Factors such as wheel design, reach capabilities, and the overall weight of the robot significantly influence its mobility. It is essential to select a robot that can seamlessly adapt to the task at hand, whether it involves working on large components in a factory or conducting repairs in confined spaces.

Flexibility complements mobility, enabling a welding robot to perform various tasks without the need for extensive reconfiguration. A flexible robot should accommodate different types of welding processes and support a variety of welding tools. This adaptability is particularly valuable in environments where multiple projects may require different welding techniques over the course of a day. Programmability also plays a role in flexibility; a robot that can easily learn new tasks or be reprogrammed for different welding jobs will ultimately prove to be a more versatile asset. By prioritizing both mobility and flexibility, users can ensure that they are investing in a welding robot that meets their operational demands and enhances efficiency.

| Feature | Description | Importance | Examples |

|---|---|---|---|

| Mobility | Capability to traverse different surfaces and navigate work areas. | High | Tracks, wheels, or legs for movement. |

| Flexibility | Ability to perform various welding tasks and adapt to different positions. | High | Articulated arms or adjustable joints. |

| Payload Capacity | Weight limit the robot can carry while performing welding. | Medium | Less than 10kg, 10-25kg, more than 25kg. |

| Power Source | Type of power supply used by the robot (battery, electric). | Medium | Corded vs. cordless options. |

| Ease of Use | How user-friendly the robot's interface and operation are. | High | Touchscreen controls vs. manual adjustments. |

| Programming Options | Methods available for programming the robot for tasks. | High | Remote control, software programming, or teach and repeat modes. |

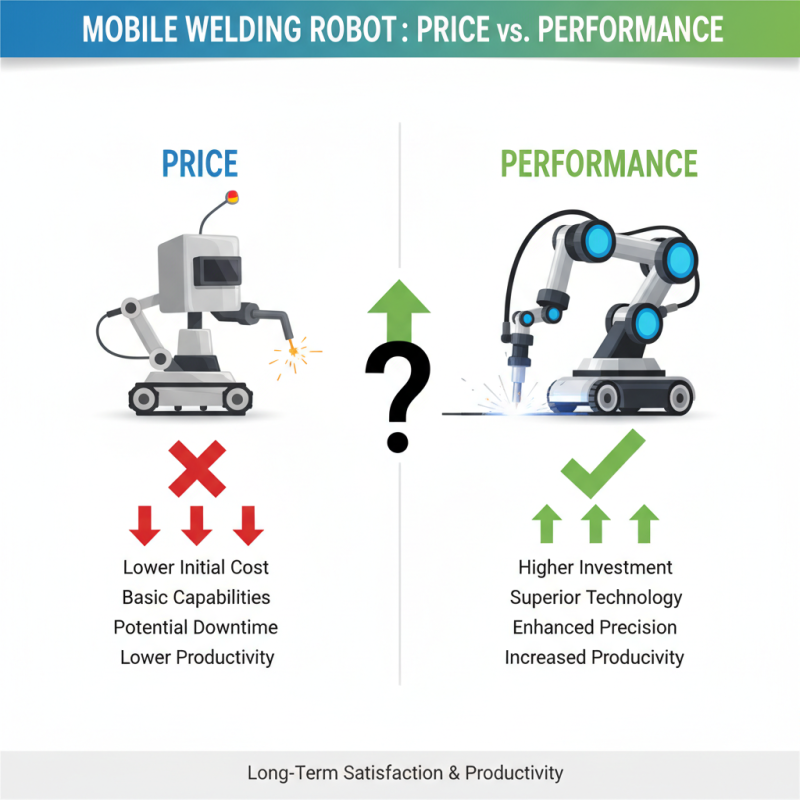

When selecting a mobile welding robot, the choice between price and performance is crucial for ensuring long-term satisfaction and productivity. While it might be tempting to opt for a lower price point, it’s important to consider the capabilities and efficiency of the robot. Investing in a higher-priced model often means superior technology, improved precision, and advanced features that can significantly enhance welding quality and speed. A well-performing robot can streamline operations, reduce downtime, and ultimately lead to cost savings in the long run.

On the other hand, assessing your specific needs is essential before making a decision. Smaller projects or occasional use may not justify the investment in high-end models, where more affordable options could suffice. Conversely, for high-volume production environments where performance is paramount, the initial higher cost of a robust robot can pay off through increased productivity and reduced rework. Therefore, it’s important to strike a balance, evaluating both the potential return on investment and the performance requirements of your welding projects to find a solution that meets your needs effectively.

When selecting a mobile welding robot, an essential aspect to consider is the reputation of the manufacturer. A well-established company often indicates reliability and the potential for better quality products. Researching the manufacturer involves looking into their history, customer reviews, and overall standing in the industry. It’s beneficial to examine how long they have been in the market, the innovations they have contributed, and whether they have specialized experience in mobile welding solutions. Positive feedback from existing customers can provide insights into the performance and durability of the robots, which are crucial in making an informed decision.

Customer support options also play a critical role in choosing the best mobile welding robot. A manufacturer that provides comprehensive support demonstrates their commitment to customer satisfaction. Look for options like technical assistance, training programs, and warranty services, as these can significantly affect your operational efficiency. Having access to knowledgeable customer service representatives can ease the troubleshooting process, ensuring minimal downtime in your welding operations. It's wise to inquire about the availability of support during the initial stages of your decision-making process, as reliable customer support can enhance the overall value of the investment in the long term.