Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

In today's rapidly evolving manufacturing landscape, robotic welding is emerging as a cornerstone technology, enhancing precision and efficiency in production processes. As companies increasingly adopt automation, the demand for skilled professionals in robotic welding is on the rise, making "robotic welding classes" a crucial step for those looking to advance their careers in this dynamic field. According to industry expert Dr. Emily Hargrave, a leading authority in automation technologies, "Investing in robotic welding classes not only equips individuals with essential skills but also opens up a plethora of career opportunities as industries adapt to advanced manufacturing techniques."

These classes provide hands-on training in operating and programming robotic welding systems, ensuring that participants are well-prepared to meet the industry's challenges and innovations. Through these programs, students gain valuable insights into the mechanics of robotic welding, safety protocols, and the integration of these machines into existing workflows. As the industry seeks to bridge the skills gap, understanding the principles taught in robotic welding classes will enable aspiring technicians and engineers to contribute effectively to their organizations' success. With the right training, the future looks bright for those embarking on a career in robotic welding.

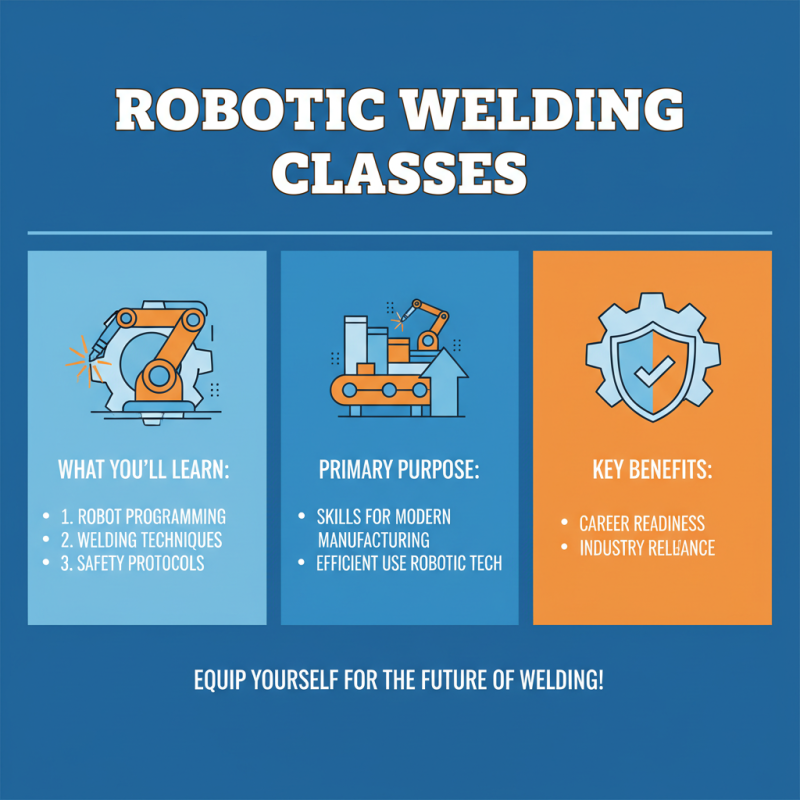

Robotic welding classes are specialized educational programs designed to teach individuals the intricacies of operating robotic systems for welding applications. These classes cover a wide range of topics that include the programming of robotic welders, understanding welding techniques, and learning about safety protocols in an industrial environment. The primary purpose of these classes is to equip participants with the technical skills and knowledge required to efficiently use robotic welding technology, which is increasingly prevalent in various manufacturing sectors.

In the modern industrial landscape, robotic welding has become a crucial component due to its ability to enhance precision, increase productivity, and reduce labor costs. By enrolling in robotic welding classes, individuals gain insight into the operation and maintenance of robotic systems, which are essential for industries looking to optimize their production processes. Moreover, these classes often include hands-on training, giving students a practical understanding of how robotic welding equipment functions in real-world settings. This training not only enriches the learner's skill set but also significantly improves their employability in a market that increasingly demands automation expertise.

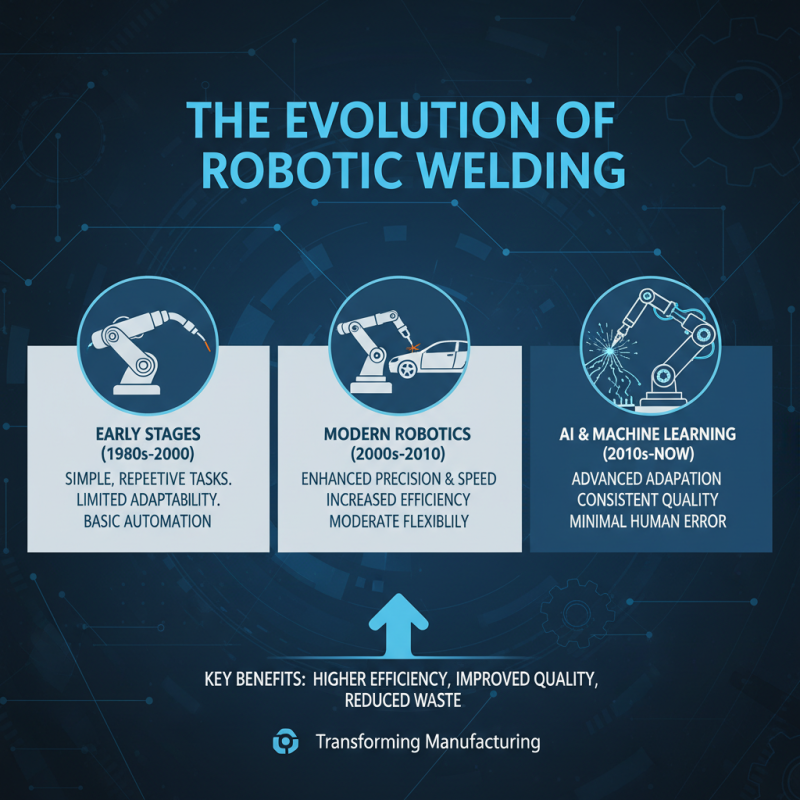

The evolution of robotic welding technology has significantly transformed the manufacturing industry. Over the past few decades, advancements in robotics have led to enhanced precision, increased speed, and higher efficiency in welding operations. Initially used for simple tasks, robotic welding systems now incorporate advanced AI and machine learning capabilities, allowing them to adapt to various welding conditions and improve their performance over time. This technological shift not only minimizes human error but also ensures consistent quality, making robotic welding an essential component of modern fabrication processes.

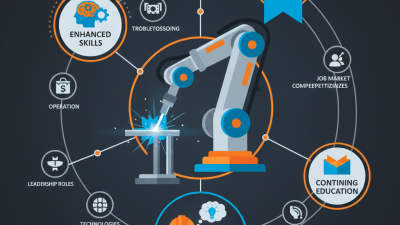

For those interested in pursuing a career in welding, gaining knowledge and skills in robotic welding can provide a competitive edge. As industries increasingly adopt robotic solutions, the demand for trained professionals who can operate and maintain these systems is growing. Taking robotic welding classes can not only enhance your technical know-how but also equip you with the necessary skills to manage and troubleshoot these advanced machines.

Tips for success in robotic welding education include seeking hands-on experience through internships or practical workshops. Familiarizing yourself with the latest welding software and programming languages is also beneficial, as it will prepare you for the evolving industry. Additionally, staying updated on industry trends and advancements will keep your skills relevant and valuable to potential employers.

Robotic welding classes are designed to equip students with essential skills that are increasingly valuable in today's manufacturing landscape. One of the key skills taught in these classes is proficiency in programming robotic welding systems. Understanding how to configure and operate these machines allows individuals to streamline production processes, reduce errors, and enhance efficiency. This technical knowledge not only boosts their competency in the workplace but also prepares them for various roles within the industry as automation continues to grow.

Another vital area of focus in robotic welding classes is troubleshooting and maintenance. Students learn to diagnose common issues that may arise during welding operations and how to implement effective solutions. This hands-on experience fosters a problem-solving mindset, making graduates more attractive candidates for employers looking for skilled technicians. Additionally, classes often cover safety protocols and quality control measures necessary to ensure safe and consistent production outcomes.

Mastering these skills can significantly enhance a student’s career advancement opportunities, paving the way for roles such as welding engineer, automation specialist, or production supervisor.

The demand for welding professionals, particularly those skilled in robotic welding, is on the rise. According to the Bureau of Labor Statistics, the welding job market is projected to grow by 8% from 2020 to 2030, which is faster than the average for all occupations. This growth is driven by the increasing use of robotics in manufacturing, as industries seek to enhance efficiency and precision. As companies invest in automation technologies, the need for workers who can operate and maintain these robotic systems is becoming vital.

Salary expectations for welding professionals also reflect this demand. The median annual wage for welders, cutters, solderers, and brazers was approximately $44,190 as of May 2020. However, those specializing in robotic welding can command higher salaries, often exceeding $60,000 annually. With advanced training and skills in robotic systems, welders may access even more lucrative opportunities, as industries like automotive and aerospace are particularly inclined to hire professionals with expertise in robotic applications. Investing in robotic welding classes not only equips individuals with valuable skills but also places them at the forefront of a thriving industry, aligning their career paths with the evolving landscape of manufacturing and technology.

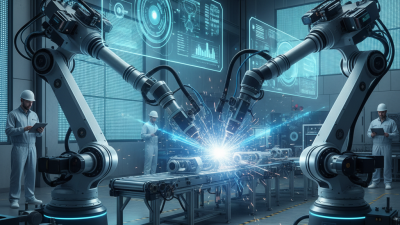

Robotic welding has revolutionized the manufacturing landscape by significantly enhancing efficiency and precision in production processes. According to a report from the International Federation of Robotics, the use of industrial robots, including those designed for welding applications, has increased by over 15% annually in some sectors. This surge is largely attributed to the ability of robotic systems to maintain consistent quality and speed, which reduces production time and minimizes the likelihood of errors when compared to manual welding. In environments where high levels of accuracy and repeatability are crucial, robotic welding demonstrates its superiority, allowing manufacturers to meet the rigorous standards demanded by modern industries.

Furthermore, the integration of robotic welding technology contributes to an overall reduction in operational costs. The American Welding Society estimates that companies can save up to 30% in labor costs by implementing automated welding systems. This cost efficiency does not come at the expense of safety; in fact, robotic systems can perform hazardous tasks, thereby protecting human workers from dangerous working conditions. Additionally, the deployment of these technologies often leads to an increase in output without the need for significant increases in workforce size, making robotic welding a wise investment for businesses aiming to remain competitive in the fast-evolving market.