Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

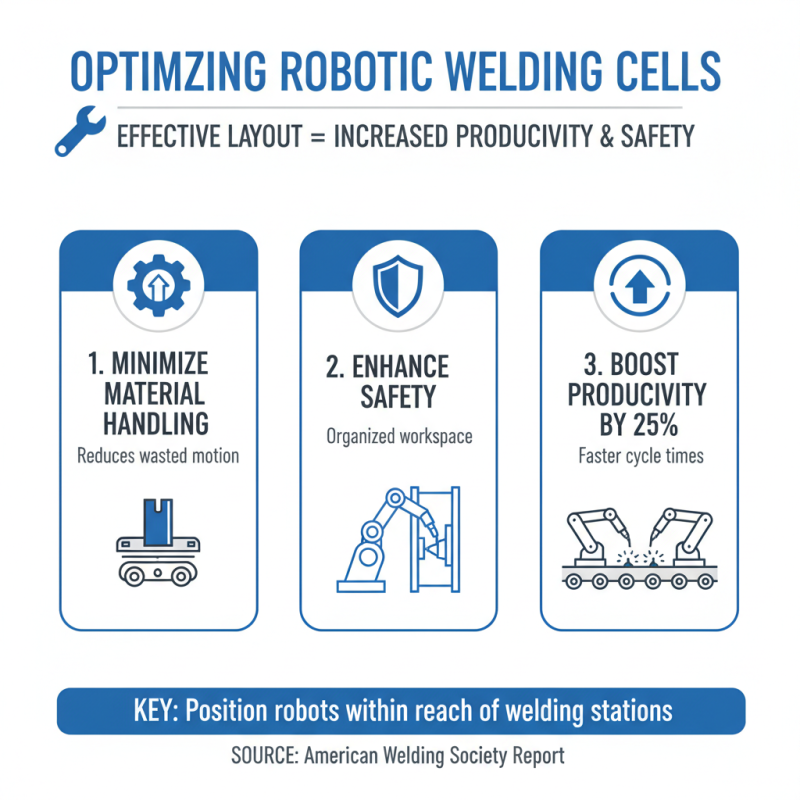

Optimizing a robotic welding cell is essential in today's manufacturing landscape. Efficient robotic welding not only enhances production rates but also improves quality and reduces costs. Each robotic welding cell has unique challenges that require careful consideration.

To achieve maximum efficiency, it's important to evaluate the layout. An organized workspace minimizes unnecessary movements and speeds up operations. Additionally, the choice of welding parameters can greatly affect performance. Selecting the right settings is crucial but often overlooked.

Training operators on the intricacies of the robotic welding cell is vital. Mistakes can happen, and learning from them fosters improvement. Regular maintenance of the equipment also ensures reliability. A small issue can lead to significant downtime. In short, there’s always room for reflection and adjustments in optimizing a robotic welding cell.

Optimizing the robot utilization rate is crucial for maximizing welding output efficiency. A well-functioning robotic welding cell must keep the robots engaged with minimal downtime. Common issues can arise, leading to inefficiencies. For example, if robots frequently pause for maintenance or programming, productivity suffers.

Regularly monitor robot performance metrics. Identify patterns of inactivity and address them. One effective way is to establish a preventive maintenance schedule. This can dramatically reduce unexpected robot downtimes. Additionally, consider the workflow design. Aligning processes to minimize travel time for the robot can also enhance efficiency.

Training operators is another key aspect. An untrained operator may underutilize the robotic system, leading to slow output. Encourage them to provide feedback on the operations. They may spot areas for improvement that automation can’t capture. A culture of continuous improvement can transform your welding cell, making it more productive.

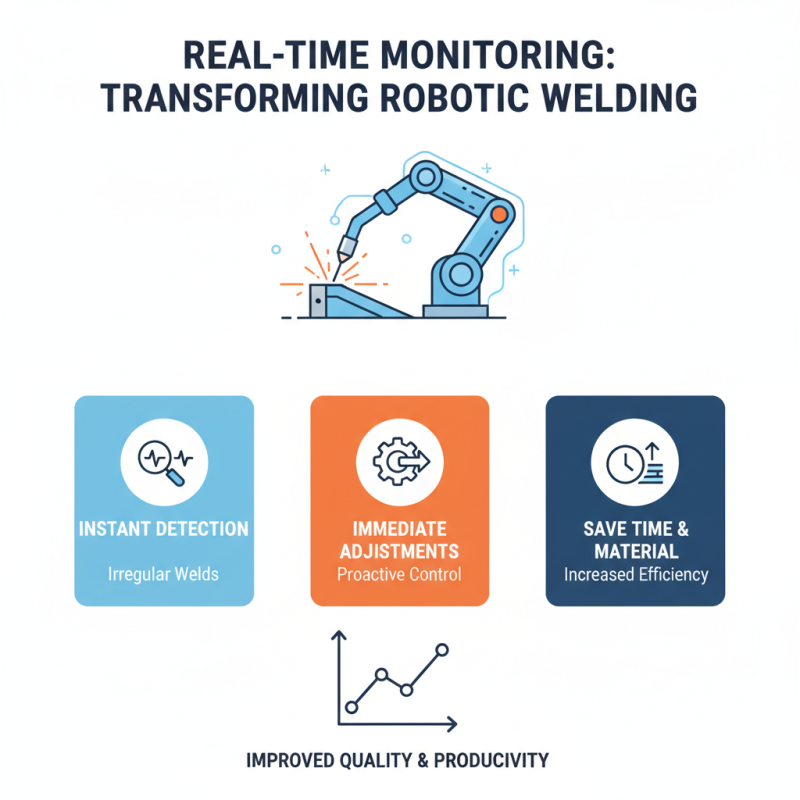

Real-time monitoring can transform robotic welding cells. By integrating sensors and feedback systems, operators can observe processes as they unfold. This allows for immediate adjustments rather than waiting for post-production analysis. An irregular weld can be detected instantly, saving time and material. Operators can become proactive instead of reactive.

Enhanced process control relies on data-driven insights. Analyzing real-time data helps identify inefficiencies. Variability in welding speed or heat levels can lead to defects. Without monitoring, these issues might go unnoticed. Regular maintenance schedules can be adjusted based on the operational data collected. This can prevent unexpected downtime and keep production flowing seamlessly.

However, implementing such systems isn't without challenges. Initial setup costs can be high, and training staff may take time. Not all data collected will be relevant. Operators must learn to discern which metrics truly impact performance. Continuous reflection on these processes is essential for optimization. Only through ongoing adjustments can maximum efficiency be achieved.

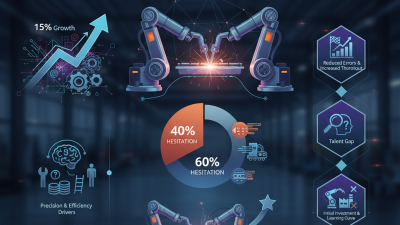

Investing in advanced welding technologies can significantly enhance production quality. Modern robotic welding systems offer precision that manual welders often cannot match. With the right setup, manufacturers can achieve cleaner seams, stronger bonds, and reduced defects. However, transitioning to these technologies is not always straightforward.

It's essential to evaluate your current processes before making the leap. Many companies overlook the need for proper training. Operators must understand how to program and troubleshoot advanced machines. Neglecting this can lead to wasted resources and underperformance. Small mistakes may amplify over time, affecting overall output and quality.

Regular maintenance of welding equipment is also crucial. Over time, wear and tear can compromise performance. Scheduling frequent checks can prevent unexpected downtimes and costly repairs. Being proactive about equipment care can promote longer lifespan and better productivity. Embracing advanced welding techniques means continuous learning and adaptation.

Optimizing your robotic welding cell starts with an effective layout. A well-planned workspace minimizes material handling and enhances safety. According to a report by the American Welding Society, an organized layout can boost productivity by up to 25%. Positioning robots within reach of welding stations reduces cycle times and increases throughput.

Next, consider workflow streamlining. Implementing a lean manufacturing approach often reveals inefficiencies. For example, studies show that eliminating unnecessary movements can reduce operational costs by 20%. Identify bottlenecks in your current processes. Analyze where delays occur. Sometimes, a simple repositioning of tools or fixtures can make a significant difference.

In any optimization effort, it’s crucial to reflect on current practices. Are workers spending excessive time searching for tools? Are there too many steps in material transfer? Gathering feedback from operators can reveal valuable insights. Engaging team members in the redesign process often leads to innovative solutions. The goal is not just efficiency, but creating a workspace that feels intuitive and organized. Remember, there's always room for improvement.

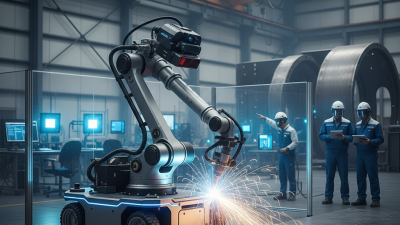

Training operators for better integration with robotic systems is crucial in maximizing efficiency within a robotic welding cell. According to a recent report by the International Federation of Robotics, companies investing in operator training see a 25% increase in productivity. This statistic underscores the importance of well-trained personnel. Operators familiar with robotic systems can troubleshoot issues faster and ensure seamless operation.

Effective training programs should focus on hands-on experience. Simulations and real-world scenarios help operators understand the machines better. Visual aids can enhance learning. Moreover, frequent training sessions keep operators updated on the latest technologies and practices. It's essential to address the gaps in knowledge that can lead to inefficiencies. Without proper training, operators may struggle to adapt to new systems, leading to increased downtime.

In an ideal world, every operator would master the robotic systems they work with. However, reality shows that skill levels often vary. Some operators may require more assistance than others. Continuous feedback is necessary to gauge their comfort level. Encouraging operators to share challenges helps identify training needs. A well-integrated team can navigate the complexities of robotic welding more smoothly, ultimately driving efficiency.

| Dimension | Metric | Current Value | Target Value | Improvement Description |

|---|---|---|---|---|

| Cycle Time | Seconds per Weld | 15 | 10 | Implement advanced scheduling algorithms |

| Downtime | Hours per Week | 8 | 2 | Conduct regular maintenance and operator training |

| Weld Quality | Defects per 1000 Welds | 5 | 1 | Train operators on quality control methods |

| Overall Equipment Effectiveness (OEE) | Percentage | 60% | 85% | Optimize production scheduling |

| Operator Skill Level | Training Hours | 20 | 40 | Increase training sessions for operators |