Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

In today's manufacturing landscape, the integration of technology in traditional processes is transforming operational efficiency and productivity. One such innovation is the mobile welding robot, a tool that not only enhances welding capabilities but also reshapes how tasks are approached in various welding environments. According to John Smith, a leading expert in robotic automation, "The advent of mobile welding robots marks a significant milestone in the industry, enabling unprecedented flexibility and precision in welding applications."

As industries strive for improved outcomes, the adoption of mobile welding robots is becoming a crucial strategy. These robots come equipped with advanced features that allow them to navigate dynamic workspaces, thereby streamlining the welding process while minimizing downtime. By automating repetitive and strenuous tasks, mobile welding robots not only improve efficiency but also enhance the quality of welds, leading to superior product results.

The deployment of mobile welding robots is prompting companies to rethink their approaches to welding projects. By leveraging this technology, businesses can stay competitive in a rapidly evolving market, ensuring that they meet both customer demands and internal production goals. The future of welding is indeed here, and mobile welding robots are at the forefront of this revolution.

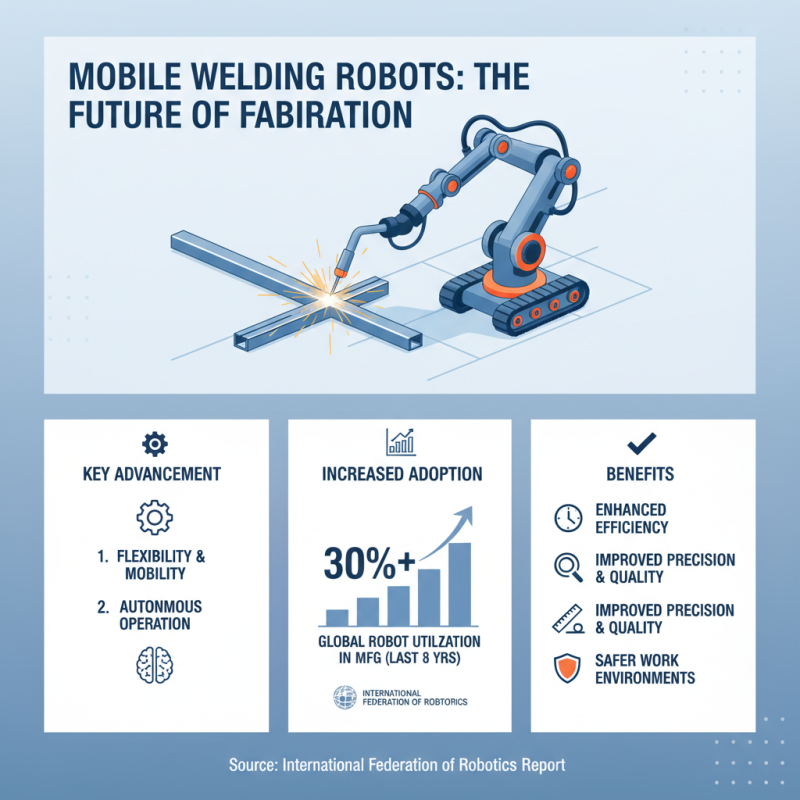

Mobile welding robots represent a significant advancement in the field of automation, providing flexibility and efficiency that traditional welding methods cannot match. These robots are designed to operate in various environments, often equipped with wheels or tracks that enable them to move freely to different work sites. According to a report by the International Federation of Robotics, the utilization of robots in manufacturing, including mobile welding solutions, has increased by over 30% in recent years, showcasing a growing trend towards automation in the industry.

One key advantage of mobile welding robots is their ability to enhance productivity. A study by the American Welding Society indicates that automation in welding can lead to a productivity increase of up to 40%. By integrating mobile welding robots into workflows, companies can minimize downtime typically associated with setting up traditional welding stations. Additionally, these robots are equipped with advanced sensors and programming that enable precise and consistent welds, significantly reducing the potential for human error and ensuring higher quality outputs. The growing adoption of mobile welding solutions reflects the industry's shift towards embracing technology to meet the demands of modern manufacturing while maintaining high safety and quality standards.

Mobile welding robots have gained traction in the manufacturing industry due to their ability to enhance operational efficiency significantly. One of the key features of these robots is their flexibility, allowing them to be deployed in various environments, from small workshops to large industrial facilities. According to a report by Market Research Future, the global mobile robotics market is expected to reach approximately $23 billion by 2025, with welding applications representing a substantial portion of this growth. This adaptability is crucial in industries where the production line is often subject to change, minimizing downtime and labor costs.

Moreover, mobile welding robots are designed with advanced automation capabilities, such as real-time monitoring and adaptive programming. These features enable them to maintain high levels of precision and consistency, which are critical in ensuring quality outputs. A recent study from the American Welding Society revealed that integrating automation in welding processes could enhance productivity by up to 30%, while also significantly reducing error rates. The incorporation of such technology not only contributes to better resource management but also supports skilled workers by taking over repetitive and physically demanding tasks, ultimately leading to a more efficient and ergonomic working environment.

Mobile welding robots are transforming the manufacturing landscape by enhancing efficiency and productivity in welding operations. According to industry reports, automating welding processes can increase productivity by up to 30%, enabling businesses to meet growing demand without sacrificing quality or safety. These robots are designed to navigate various work environments, allowing them to perform intricate welding tasks in spaces where traditional methods may fall short. The flexibility of mobile welding robots means they can be deployed for various applications, from automotive manufacturing to construction, significantly streamlining the workflow.

One of the most notable benefits of utilizing mobile welding robots is the reduction in labor costs. A report from the National Institute of Standards and Technology indicates that companies adopting robotic welding technologies experience a 20% to 50% decrease in labor expenses. Furthermore, these robots maintain consistent weld quality, which is crucial for reducing rework and material waste. With the ability to operate continuously, mobile welding robots also contribute to enhanced throughput, allowing companies to achieve higher output levels. As industries move towards greater automation, the integration of mobile welding robots presents a compelling opportunity to improve operational efficiency and drive competitive advantages.

| Feature | Description | Efficiency Benefit |

|---|---|---|

| Portability | Easily movable between job sites. | Reduces travel time and setup time. |

| Precision | High level of accuracy in welding. | Minimizes waste and rework. |

| Automation | Automated welding processes with minimal human intervention. | Increases production rates and lowers labor costs. |

| Consistency | Delivers consistent quality in welds. | Ensures reliable results across multiple projects. |

| Safety | Reduces human exposure to hazardous welding conditions. | Improves workplace safety and reduces accident rates. |

| Versatility | Capable of performing various welding tasks. | Can adapt to different projects and materials easily. |

Mobile welding robots are revolutionizing various industries by enhancing efficiency and productivity in welding processes. In the automotive sector, for instance, these robots facilitate high-speed welding in the assembly line, significantly reducing time while maintaining precision. Their ability to perform repetitive tasks consistently helps ensure uniform quality across hundreds or thousands of vehicles, which is critical for safety and performance standards.

In the construction and manufacturing industries, mobile welding robots are increasingly employed for their versatility and adaptability. They can maneuver in tight spaces and on uneven surfaces, making them ideal for complex structural projects. By automating welding tasks, companies can address labor shortages and reduce human exposure to hazardous environments. This not only increases operational safety but also allows skilled workers to focus on more complex and creative tasks, ultimately driving innovation within the field.

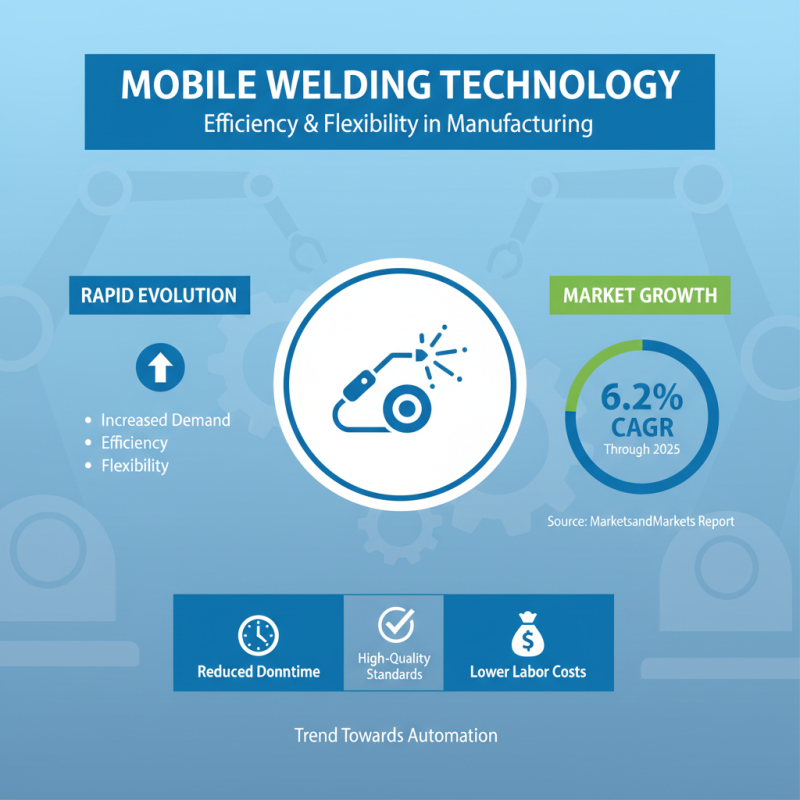

Mobile welding technology is rapidly evolving, driven by the increasing demand for efficiency and flexibility in manufacturing processes. According to a recent industry report by MarketsandMarkets, the mobile welding market is projected to grow at a compound annual growth rate (CAGR) of 6.2% through 2025. This growth reflects a significant trend towards automation in welding operations, enabling manufacturers to significantly reduce downtime and labor costs while maintaining high-quality standards.

Future trends in mobile welding technology will likely focus on enhancing automation capabilities through advanced robotics and artificial intelligence. These innovations allow machines to learn and adapt to different welding scenarios, optimizing parameters for various materials and joints. Furthermore, the integration of IoT (Internet of Things) technology facilitates real-time monitoring and remote diagnosis, empowering companies to minimize disruptions and enhance productivity. As mobile welding robots become more sophisticated, their applications are expected to expand into sectors like construction, shipbuilding, and repair, which demand versatile and efficient solutions.

**Tips:** When considering the implementation of mobile welding robots, assess your current welding processes to identify bottlenecks and inefficiencies. Investing in training for your workforce to collaborate effectively with automated systems will also be crucial for maximizing the benefits of automation. Additionally, staying informed about the latest advancements in welding technology can help your business remain competitive in an evolving market.