Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

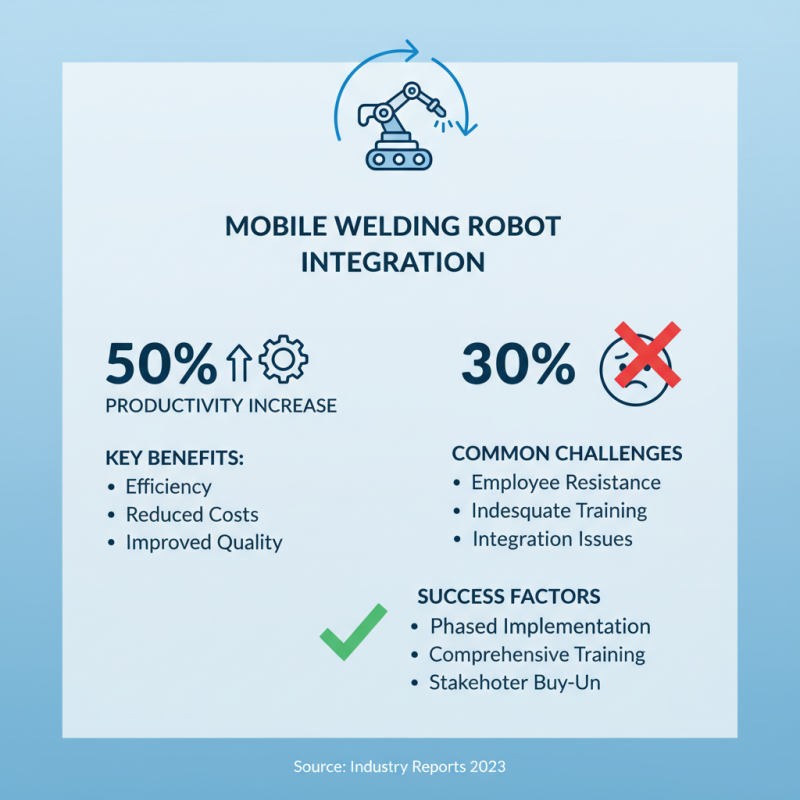

The mobile welding robot has transformed the welding industry. This technology enhances efficiency in various environments. Companies seek to maximize productivity and safety while minimizing human error.

Implementing a mobile welding robot comes with challenges. Training staff to operate these robots effectively is crucial. Workers must understand both the technology and safety protocols. It's important to acknowledge that even with advanced tools, accidents can occur.

Safety measures must evolve with technology. Regular maintenance and inspections are essential. Awareness of potential hazards is critical. A mobile welding robot does not eliminate risks but can mitigate them. The goal is to create a safer, more efficient work environment. Embracing both the advantages and limitations of this technology will lead to better outcomes.

Mobile welding robots are transforming industrial applications. They not only increase efficiency but also boost safety. With these robots, businesses can reduce production time and minimize human error. They are designed to work in various environments, adapting to different tasks easily.

Using mobile welding robots helps in maintaining consistent quality. These machines can execute precise welds repeatedly. This reduces the likelihood of defective products. However, companies must ensure proper training for their operators. A knowledgeable team can maximize the robots' capabilities while minimizing potential risks.

Tips for successful integration include assessing workspace layouts. Clear paths should facilitate movement. Regular maintenance of robots is crucial. Performing checks can prevent unexpected breakdowns. Lastly, safety protocols must be updated to include robot operations. Ignoring these factors can lead to accidents or delays in production.

Mobile welding robots can significantly enhance productivity in various environments. These machines assist with precision and speed that human welders may struggle to match. Equipped with advanced sensors, they can adapt to different materials and weld types seamlessly. High-definition cameras allow for real-time monitoring and adjustment, reducing errors. This means less time spent on rework.

Additionally, safety features are paramount. Many robots incorporate protective barriers to prevent accidents. Emergency shut-off switches are crucial. They must be easily accessible. Operator training is essential, despite the robot's efficiency. Workers should understand how to handle both the machine and its limitations. Regular maintenance checks are necessary to ensure optimal performance. Neglecting these tasks can lead to unpredictable malfunctions.

Incorporating AI technology can further improve the decision-making process. However, AI should not completely replace human oversight. Every system has flaws and requires constant improvement. Understanding these imperfections can enhance overall effectiveness. User feedback is invaluable in this regard. By continuously testing and refining processes, mobile welding robots will become even more efficient and safer.

| Feature | Description | Benefits | Impact on Efficiency |

|---|---|---|---|

| Auto-Positioning System | Automatically adjusts to various workpieces to ensure optimal welding angles. | Reduces setup time and ensures consistent weld quality. | Increases overall productivity by minimizing manual adjustments. |

| Real-Time Monitoring | Continuous monitoring of parameters such as temperature and voltage during welding. | Ensures quality control and prevents defects. | Reduces rework and material waste, leading to cost savings. |

| Safety Features | Includes automatic shut-off and emergency stop functions. | Enhances operator safety and compliance with regulations. | Minimizes downtime due to accidents and legal issues. |

| Mobile Platform | Designed for easy movement across job sites. | Increases flexibility and adaptability to different working environments. | Streamlines workflow by reducing transport time. |

| User-Friendly Interface | Intuitive controls for easy operation and adjustments. | Reduces training time and improves confidence in operation. | Enhances overall efficiency by enabling quick adaptations to various tasks. |

Mobile welding robots have become vital in modern manufacturing, yet their safe operation requires strict adherence to safety protocols. According to a recent industry report, 30% of workplace accidents in welding involve improper robot management. Guidelines can significantly reduce these incidents.

Welders should undergo training focused on robotic systems. Understanding the technology is crucial. Simple mistakes, like failing to secure the workspace, can lead to serious injuries. A clean area is essential. It's notable that 50% of accidents are linked to cluttered workspaces. Regular checks of equipment also matter. Regular maintenance prevents malfunctions.

Implementing standard operating procedures (SOPs) is another key aspect. These ensure that all team members follow the same protocols. Easy-to-understand visuals can help. Reminders can reinforce safety. Encouraging feedback can identify areas needing improvement, fostering a culture of safety. Emphasizing communication can close gaps that lead to accidents.

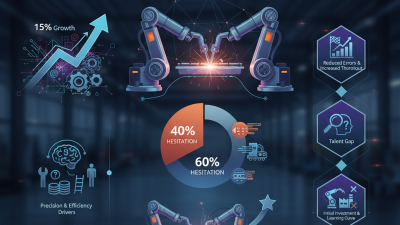

Integrating mobile welding robots into existing workflows can drive efficiency. Many companies reported a productivity increase of up to 50% after adopting these technologies. This is significant. However, not all integration efforts succeed. One study noted that 30% of businesses faced challenges, such as employee resistance or inadequate training.

The transition to mobile welding robots requires careful planning. Setting clear goals is essential. It helps employees adapt and reduces frustration. Furthermore, focusing on connectivity with current systems is key. Data shows that 70% of successful integrations involved seamless communication between robots and human operators. This not only enhances safety but also streamlines the welding process.

Training staff is crucial. Continuous education improves robot utilization rates. Workers often hesitate to embrace new technology without proper guidance. In one survey, 40% of employees expressed concerns about robotics replacing their jobs. It highlights the need for inclusive training programs that address fears while promoting collaboration. Fostering a culture of innovation requires time and patience. Without it, the full potential of mobile welding robots may remain untapped.

Mobile welding robots are becoming essential in various industries due to their efficiency and precision. However, their performance heavily relies on proper maintenance practices. Regular checks can avoid costly downtime and enhance safety. A well-maintained robot can reduce failure rates by up to 50%, according to industry reports.

One important tip is to clean the robot regularly. Dust and debris can interfere with sensors and joints, leading to inaccuracies in welding. Ensure the welding torch and wire feeders are free from spatter and buildup. This simple act can prolong tool life significantly.

Another crucial aspect is lubrication. A lack of lubrication can lead to excessive wear on gears and motors. Check lubrication points per manufacturer specifications, and follow recommended intervals. This care can ultimately prevent mechanical failures and maintain operational efficiency.

Adopting these maintenance practices will help extend the lifespan of your mobile welding robot. You will notice better performance and fewer interruptions in work. A proactive approach addresses potential issues before they become major problems, ensuring a safer and more effective working environment.