Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

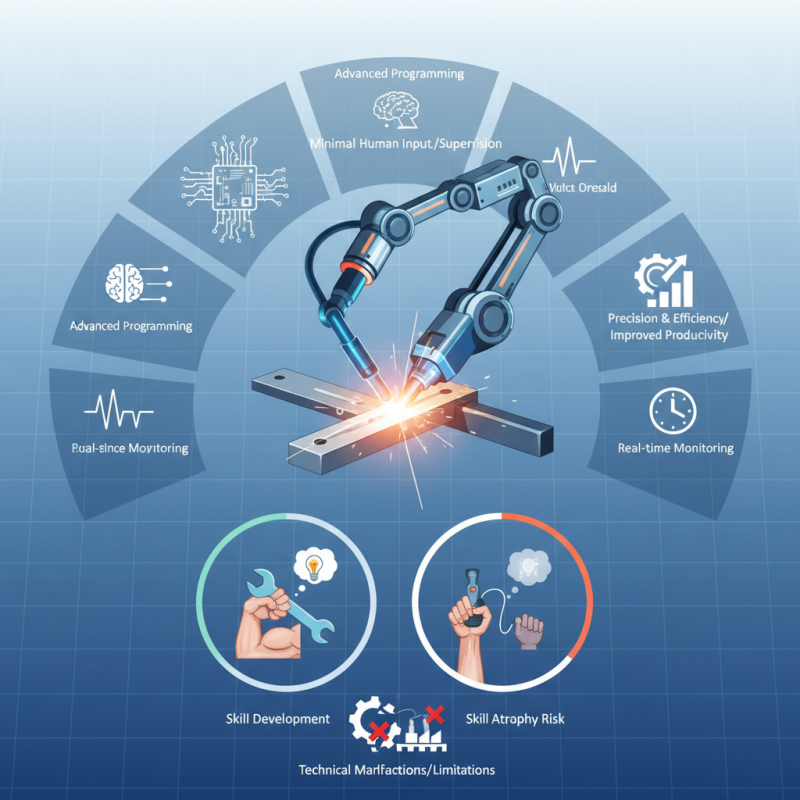

The Lincoln robotic welder is a marvel of modern technology. It automates the welding process, ensuring precision and efficiency. This machine is a game changer for industries that rely on high-quality welds. With its advanced programming, it can perform complex tasks with minimal human input.

Welding can be challenging. It requires a steady hand and deep knowledge. The Lincoln robotic welder takes away much of this burden. Operators can focus on supervising the work rather than executing it manually. However, relying too much on automation may lead to skill atrophy in workers.

The design and functionality of the Lincoln robotic welder offer various features. From programmable welding patterns to real-time monitoring, each aspect is geared toward improving productivity. Despite its advantages, the machine faces limitations. Technical malfunctions can halt production. Understanding how it works is essential for operators and managers alike.

A Lincoln robotic welder is an automated machine designed for welding tasks. It significantly enhances precision and efficiency in the welding process. Unlike manual welding, robotic welders operate consistently. They can perform intricate tasks with minimal human intervention. This reduces the risk of human error. Robotic welders work through programmed movements and advanced sensors. They adapt to various welding techniques and materials.

Tips: Ensure your workspace is safe and organized. Clean the area around the welder regularly. This prevents accidents and improves efficiency.

The setup of a robotic welder can be intricate. Training operators is essential. They need to understand programming and maintenance. Lack of knowledge can lead to mistakes. Sometimes, even experienced operators overlook simple issues. Regularly updating operators on new techniques is crucial.

Tips: Keep a checklist for daily operations. This helps in identifying potential problems early. Consider routine training sessions to refresh skills and knowledge.

Lastly, remember that a robotic welder is not infallible. Regular inspections are necessary. Components can wear out, affecting performance. A proactive approach to maintenance can minimize downtime. A robotic welder can transform productivity but requires attention and care.

Robotic welding technology has advanced significantly. A robotic welder consists of several key components that work together to ensure precision and efficiency. The robotic arm is often the most recognizable part. It's designed to mimic human movements but with greater accuracy and speed. According to industry reports, robotic arms can operate with a repeatability of ±0.005 inches, which significantly reduces the likelihood of defects.

Another essential element is the welding power source. This device delivers the necessary energy for the welding process. The power source must match the material being welded. Various studies indicate that the correct settings can boost productivity by up to 30%. However, finding the right balance between voltage, current, and speed requires constant adjustments.

Welding torches are also vital. They are equipped with welding wire and nozzles that focus the arc precisely where needed. A report from a leading robotics firm highlighted that improper torch setup can lead to inconsistent weld quality. Regular maintenance of these components is necessary but often overlooked. Operators must continually assess performance to prevent breakdowns. They can’t simply rely on technology; human oversight remains crucial.

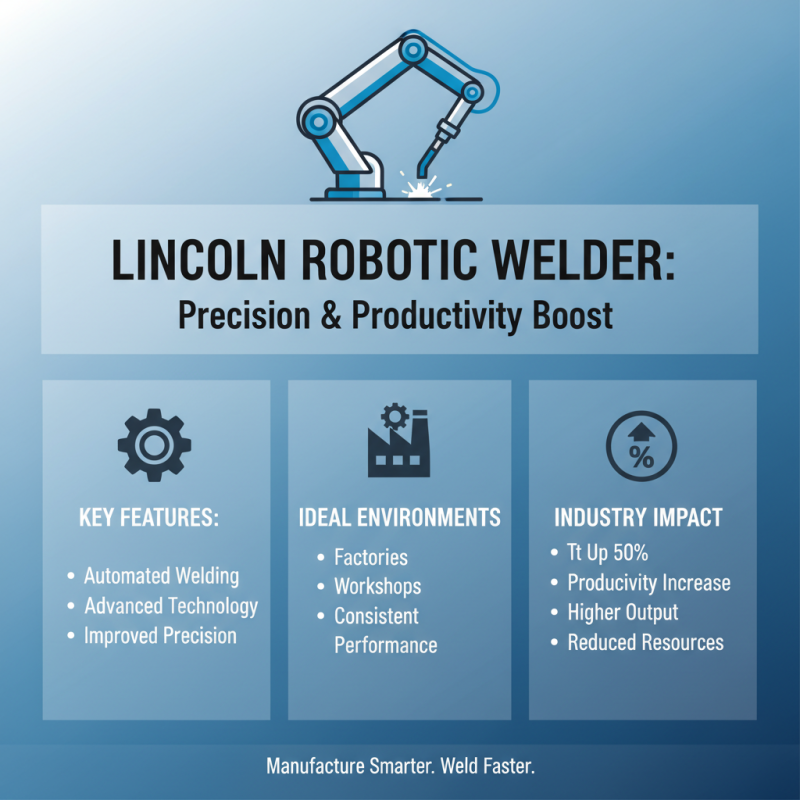

A Lincoln robotic welder is a sophisticated machine designed for automated welding tasks. These robots use advanced technology to improve precision and efficiency. Typically, they can operate in various environments, such as factories and workshops, to perform tasks consistently. Industry data suggests that robotic welding can increase productivity by up to 50% compared to traditional methods. Such increases are vital as manufacturers aim for higher output with fewer resources.

Operation begins with programming the robot for specific tasks. The operator inputs parameters for welding, including speed and material type. The robot then follows the set instructions, welding with remarkable accuracy. However, the setup phase can be complex. Mistakes in programming can lead to defects in welds. Data from a recent survey indicates that around 15% of robotic welds fail due to improper calibration. This highlights the need for skilled operators who can troubleshoot issues quickly.

Additionally, robotic welders can face challenges in adapting to different materials. For example, some metals require unique settings to be welded correctly. The robot's sensors must detect these differences. If the machine is not correctly programmed, it can produce inconsistent results. Industry reports show that 20% of automation projects struggle with material adaptability. Learning from these failures is critical for future advancements and improvements in robotic welding technology.

Robotic welders have gained popularity in manufacturing for several reasons. One major advantage is precision. These machines offer consistent weld quality, minimizing human error. Automated systems can be programmed to perform complex welds that might be difficult for a human operator to achieve consistently. This precision leads to stronger joints and improved product longevity.

Cost efficiency is another significant benefit. While the initial investment might be high, robotic systems can operate continuously. They require less downtime than human workers. This efficiency can lead to decreased labor costs over time. Additionally, robotic welders can handle repetitive tasks without fatigue. However, it's essential to consider maintenance and training costs, which can add up unexpectedly.

Flexibility in application is a noteworthy aspect. Robotic welders can be adapted for various designs and materials. They can work with metals like steel and aluminum. Yet, not every manufacturing environment is suited for robotics. Companies must assess their specific needs carefully. Adaptation sometimes requires rethinking workflow or layout, which can be a challenge.

Lincoln robotic welders are widely used across industries for their efficiency and precision. Their applications include automotive manufacturing, aerospace, and construction. In the automotive sector, they streamline the assembly line, enabling faster production rates. Each weld is performed with consistent quality, which reduces the chance of defects.

In aerospace, these welders handle complex components that require meticulous attention. Precision is vital in this field. Each component must meet strict standards. For instance, pressure vessels and fuselage parts often need flawless welds to ensure safety. The consistency offered by robotic welding makes it an ideal choice.

Tip: Always ensure regular maintenance of robotic welders. Neglect can lead to unexpected downtime.

In construction, these robots are used for fabricating steel structures. They assist in projects requiring large-scale metal work. Accuracy is paramount in this dynamic environment. However, human oversight is still necessary. Sometimes, robots can misinterpret programming, leading to errors.

Tip: Training operators to monitor and troubleshoot can reduce costly mistakes.