Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

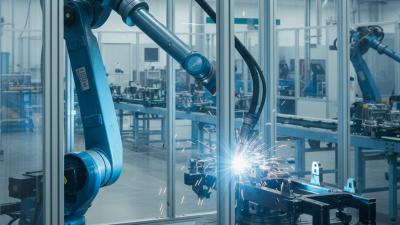

In recent years, the demand for skilled professionals in the field of robotic welding has surged, and this trend is expected to continue into 2025. As automation and advanced technologies reshape manufacturing processes, the job market is evolving, offering lucrative opportunities for those trained in robotic welding. Leading industry expert Dr. Emily Carter states, "The future of welding lies in automation; those who adapt and refine their skills will find themselves at the forefront of this revolution." This insight underscores the importance of staying informed and prepared as we approach the high-paying robotic welding jobs that will define the industry in the near future.

As companies increasingly adopt robotic systems to enhance productivity and precision, the landscape of welding jobs is changing drastically. Workers who possess a blend of traditional welding skills and technological proficiency will be highly sought after. Emphasizing the need for continuous learning and adaptation, Dr. Carter highlights that “robotic welding jobs require not just knowledge of welding principles, but also an understanding of robotics and programming.” This dual expertise is essential for those aiming to unlock the best career paths in this dynamic field. Preparing for the future in robotic welding is not just about securing a job; it’s about positioning oneself as a leader in a rapidly evolving industry.

The landscape of robotic welding jobs is evolving rapidly in 2025, driven by advancements in technology and a growing demand for automation in various industries. As companies increasingly automate their manufacturing processes, the role of robotic welding technicians is becoming more critical. These professionals are not only required to operate welding robots but also to program, maintain, and optimize these advanced systems. The integration of artificial intelligence and machine learning into welding technology means that workers need to be well-versed not only in traditional welding techniques but also in the software and programming aspects of robotics.

Moreover, the workforce demand is shifting towards those who possess a blend of technical skills and practical experience. Job seekers will need to focus on acquiring certifications in robotic welding systems and developing a deep understanding of automation technologies. Networking within industry-specific forums and participating in relevant training programs can also open doors to high-paying opportunities. As industries prioritize efficiency and precision, understanding how to leverage newer robotic systems will be essential for anyone looking to secure a lucrative position in the field. Emphasizing continuous learning and adapting to new technologies will be a key strategy for success in the evolving landscape of robotic welding jobs in 2025.

To secure high-paying robotic welding jobs by 2025, candidates must cultivate a specific set of skills and qualifications that align with industry demands. According to the American Welding Society, proficiency in advanced welding techniques, such as laser and arc welding, is increasingly sought after. Additionally, a strong understanding of robotics programming and automation is crucial, as many employers are transitioning to automated welding systems. Candidates who can design, operate, and troubleshoot robotic systems are likely to stand out in the competitive job market.

Education plays a significant role in qualification. A report from the National Center for Welding Education and Training indicates that welding professionals with an associate's degree or higher can earn, on average, 20% more than those with only a high school diploma. Certifications, especially in robotic welding technologies, can further enhance employability and potential salary. Skills in CAD software and an understanding of quality control measures are also valuable, as companies seek employees who can ensure that automated processes meet industry standards while maximizing efficiency and reducing scrap rates. As the demand for skilled robotic welders continues to grow, these essential qualifications will be key to landing lucrative positions in the field.

As we approach 2025, the demand for robotic welders is expected to surge across various industries, driven by advancements in automation and the need for increased efficiency. Key sectors such as automotive manufacturing, aerospace, and construction are leading the way in hiring robotic welders, as companies seek to enhance productivity and reduce labor costs. The automotive industry, in particular, is continuously integrating advanced welding technologies into production lines, creating numerous high-paying job opportunities for skilled professionals.

Tips for aspiring robotic welders include focusing on obtaining relevant certifications that demonstrate your expertise in robotic welding techniques and equipment. Additionally, gaining experience through internships or apprenticeship programs within these key industries can significantly boost your employability. Networking within industry-specific associations can also provide valuable insights into job openings and emerging trends in robotic welding.

Another critical aspect is to stay updated on the latest technological advancements in robotic welding. Understanding the intricacies of programming and maintaining robotic systems can set you apart from other candidates. Continuous learning through online courses and workshops will enhance your skill set and position you as a valuable asset to potential employers. As the landscape of robotic welding evolves, staying proactive in your professional development will be essential for securing high-paying job opportunities in 2025 and beyond.

In 2025, navigating the job market for high-paying robotic welding positions will require a strategic approach, particularly as the demand for skilled workers in advanced manufacturing continues to rise. According to a recent industry study, the robotic welding market is projected to grow at a CAGR of 10.3% from 2023 to 2028, signaling a burgeoning need for professionals well-versed in automation technologies. To capitalize on this trend, job seekers should focus on developing specialized skills in robotics programming and machine maintenance, as these competencies are becoming increasingly sought after in job listings.

Networking plays a pivotal role in effective job searches in this field. Engaging with professionals through industry conferences, online forums, and regional training sessions can open doors to opportunities that may not be advertised through traditional job portals. Additionally, leveraging platforms like LinkedIn to connect with industry insiders and joining relevant groups can provide valuable insights into the latest job openings and market trends. As highlighted in a workforce development report, nearly 70% of job vacancies are filled through networking efforts rather than conventional applications, underscoring the importance of building a robust professional network.

Staying informed about technological advancements and pursuing certifications in the latest robotic welding techniques will also enhance employability. Reports indicate that graduates with certifications in automation systems are likely to command salaries that are 15-25% higher than their non-certified counterparts. By focusing on these strategies—skill enhancement, networking, and continuous learning—job seekers can position themselves favorably in the competitive landscape of high-paying robotic welding jobs in 2025.

| Job Title | Average Salary (USD) | Location | Experience Level | Top Skills Required |

|---|---|---|---|---|

| Robotic Welding Engineer | $85,000 | California | Mid-Senior Level | Welding, Robotics, CAD |

| Welding Automation Specialist | $90,000 | Texas | Senior Level | Automation, Programming, Robotics |

| Robotic Process Engineer | $80,000 | Michigan | Entry-Mid Level | Welding, Process Improvement, Research |

| Robotics Welding Technician | $70,000 | Ohio | Entry Level | Welding, Troubleshooting, Maintenance |

| Automation and Robotics Engineer | $95,000 | Illinois | Senior Level | Robotics, Engineering Design, Software |

Building a strong professional network is essential for anyone aspiring to find high-paying robotic welding jobs in 2025. Attending industry conferences, joining relevant professional organizations, and connecting with peers on platforms like LinkedIn can significantly enhance your visibility in the field. When networking, focus on building genuine relationships rather than merely exchanging contact information. This approach fosters trust and opens up potential job opportunities through referrals.

Tips: Make a habit of reaching out to industry leaders or peers after networking events. A simple thank-you email or a message expressing interest in their work can set you apart. Also, consider joining local welding clubs or online forums to engage with a broader community and stay updated on industry trends.

Professional development is another crucial element in securing valuable welding positions. Continuous learning through certifications, workshops, or advanced training can make you more appealing to potential employers. This not only showcases your commitment to the field but also ensures you stay up-to-date with the latest techniques and technologies in robotic welding.

Tips: Look for online courses or local vocational programs that offer certifications relevant to robotic welding. Setting aside time each month for professional development will help you remain competitive and informed about new advancements in your field. Engaging in skill enhancement will give you an edge when applying for high-paying positions in robotic welding.