Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

In today’s manufacturing landscape, choosing the right automated welding machine is critical for efficiency. The Global Market Insights report reveals that the automated welding market is expected to reach $10 billion by 2027. This surge highlights the growing reliance on automation in welding processes across various industries. With advancements in technology, selecting the appropriate machinery can be daunting.

Experts emphasize the importance of making informed decisions. Michael Davis, a welding automation specialist, states, "Investing in the right automated welding machine can dramatically enhance productivity and reduce costs." However, many companies overlook vital factors such as machine compatibility and maintenance needs, leading to regrets later.

The selection process isn't straightforward. Businesses face challenges in evaluating various options. It’s essential to consider production requirements alongside budget constraints. Real-world insights from industry leaders can help navigate this complexity. Understanding the key features of an automated welding machine will determine its success in your operations.

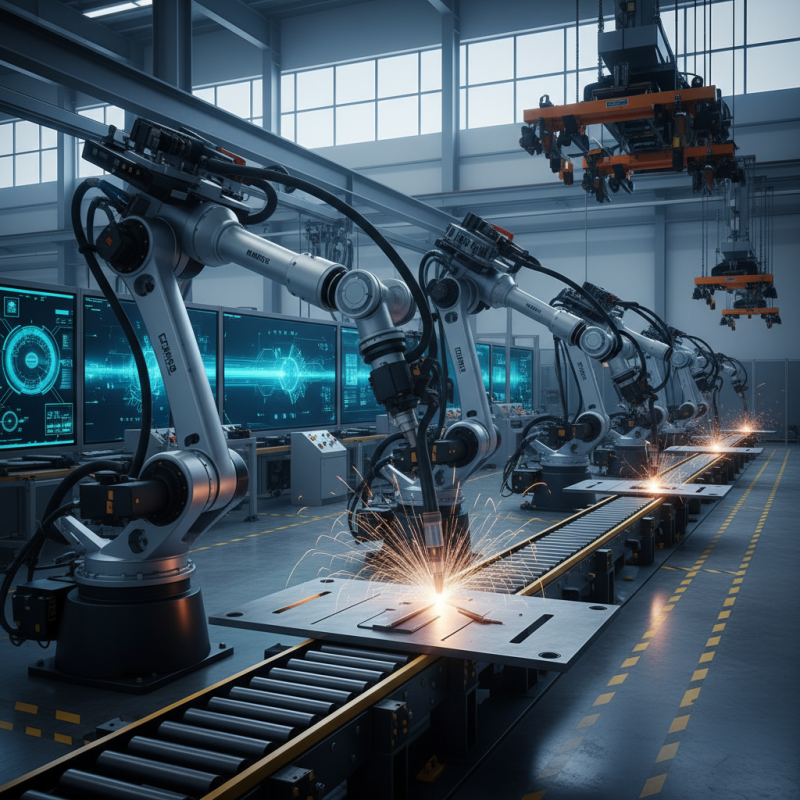

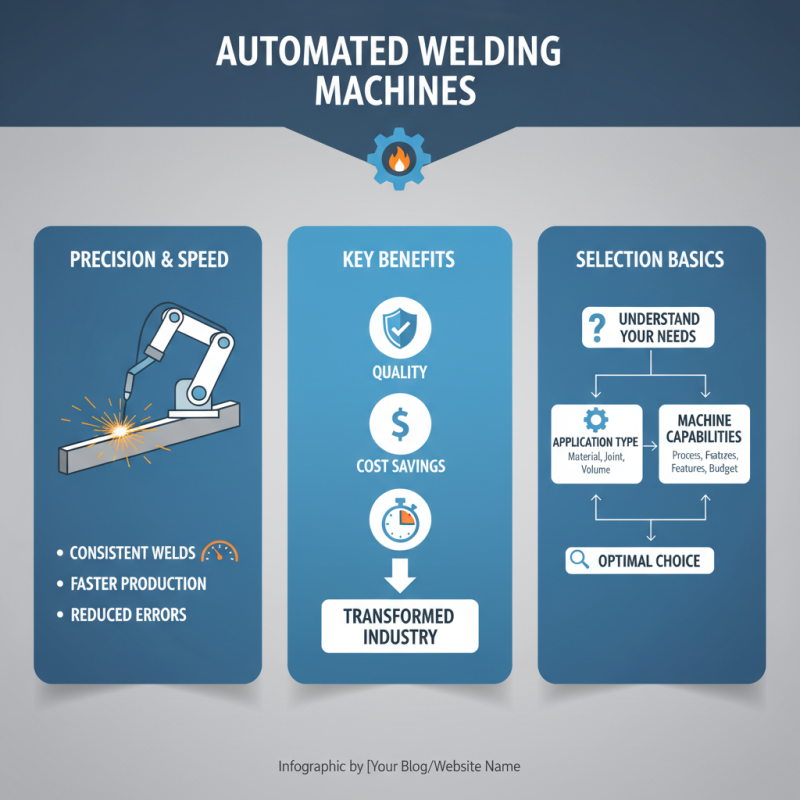

Automated welding machines have transformed the industrial landscape. They offer precision, speed, and consistency. Understanding their basics is vital for optimal selection. These machines can be complex. Knowing what you need is crucial.

When choosing an automated welding machine, consider your production needs. Different processes exist, like MIG, TIG, and arc welding. Each comes with its advantages. Think about the materials you'll be working with. It's essential to match your machine to the materials it will encounter. Sometimes, this means making tough decisions.

Another essential tip is to evaluate automation levels. Fully automated machines can boost efficiency but may require higher upfront investments. Semi-automated machines provide flexibility. Consider current and future projects. It's crucial to think ahead. If your needs grow, will your machine keep up?

Setting realistic expectations is also important. While machines improve productivity, they are not a cure-all. Human oversight is still necessary for quality control. Reflecting on these points can help you make a more informed choice.

When choosing an automated welding machine, understanding your welding needs is crucial. Various industries require different welding techniques. For instance, automotive and aerospace sectors often demand precise and high-speed welding processes. According to a recent industry report, over 30% of fabrication shops have shifted towards automated welding solutions to enhance productivity and accuracy.

Consider the materials you will be working with. Aluminum, stainless steel, or carbon steel all require specific settings and equipment. An overwhelming 65% of welders struggle with switching between materials due to improper machine adjustments. This not only affects the weld quality but also can lead to increased waste and costs.

Evaluate the volume of production as well. High-volume manufacturing facilities might value speed and efficiency more than customization. Yet, a machine that works great for mass production may not be suitable for complex projects. A study indicated that nearly 40% of users reported a need for flexibility in their equipment, which is often overlooked. Understanding these variances will help you make a more informed decision.

When evaluating an automated welding machine, the features and specifications play a crucial role. Look for adjustable welding parameters. This allows you to customize settings based on the material and project. The ability to control the welding speed and power output enhances precision. Consider machines with user-friendly interfaces for easy adjustments. Complicated controls can lead to errors.

Another important specification is the machine's duty cycle. A higher duty cycle means longer operational time without overheating. This is vital in high-volume production settings. Pay attention to the range of materials the machine can handle. Some machines perform well with thick metals, while others are better for thin sheets. Weight and portability also matter. A lighter machine might be easier to handle and move, but it may lack stability during operation.

Don't overlook the importance of safety features. Automatic shut-off systems can prevent accidents. These aspects should not be ignored, as they directly affect the working environment. Also, checking user reviews can provide insights into any recurring issues. Not all machines are perfect; each has its quirks. Reflect on your specific needs and don’t rush the decision-making. Choosing the right machine involves balancing many factors.

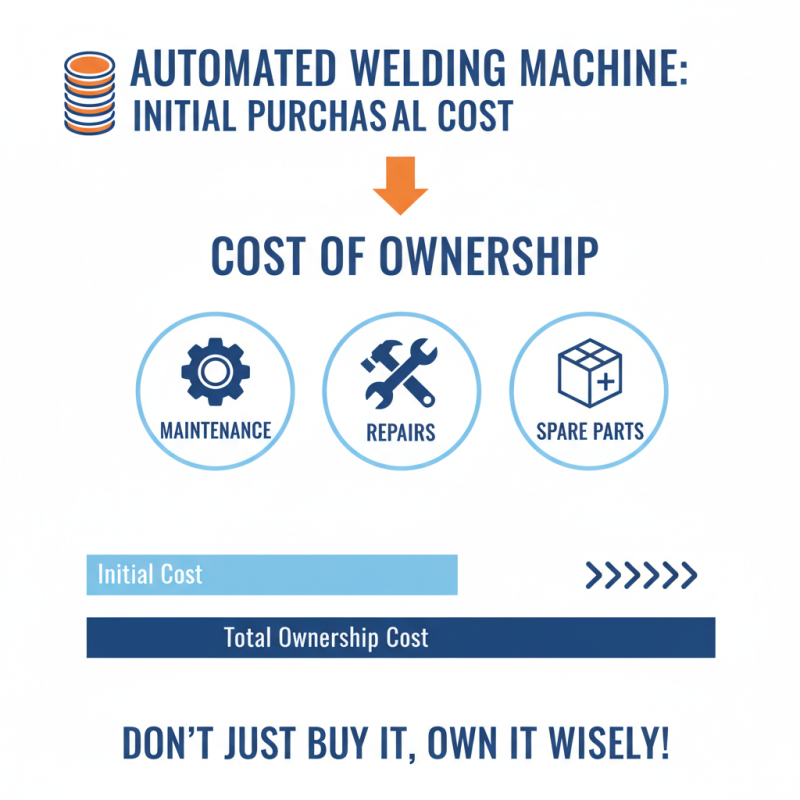

When considering an automated welding machine, the budget is a critical factor. You must evaluate the initial purchase price carefully. However, the cost of ownership often overshadows that. This includes maintenance, repairs, and essential spare parts. Ensure you factor these into your decision.

A lower upfront cost might seem attractive, but hidden expenses can accumulate. For instance, machines that require frequent repairs can drain resources quickly. Consider energy consumption as well. An energy-efficient model may have a higher price tag but will save you money long-term.

Look into the training costs too. Some machines need specialized training, adding to your overall budget. Don’t overlook software updates; many machines come with ongoing fees. Reflect on your specific needs. Sometimes, those budget-friendly options don't cover essential features. Pay attention to compatibility with existing setups. You might end up with unexpected costs if machines don’t integrate smoothly. Consider the long-term financial impact before making your final choice.

When selecting an automated welding machine, after-sales support and maintenance are crucial. Many buyers overlook this aspect. However, a reliable support system can save time and costs. In the long run, it can prevent machine downtime. Look for companies that offer comprehensive service packages. They should include installation, training, and routine maintenance.

Quality after-sales service is not just about fixing problems. It's about the assurance of support when issues arise. A strong team of technicians can guide you through complex repairs. They can also help with routine checks, ensuring the machine runs optimally. Consider how easily you can access these services. Is there a local support center? Can you reach technicians via phone or online?

Maintenance services should be transparent and accessible. Understand the costs associated with spare parts and repairs. Many companies provide a warranty, but terms can vary. Look for clear information about what is covered. Things are not always straightforward. Some providers may have hidden fees. Research user reviews to gauge the satisfaction of other customers. This feedback can inform your decision.

This chart displays the importance level of various factors to consider when choosing an automated welding machine, including after-sales support and maintenance services.