Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

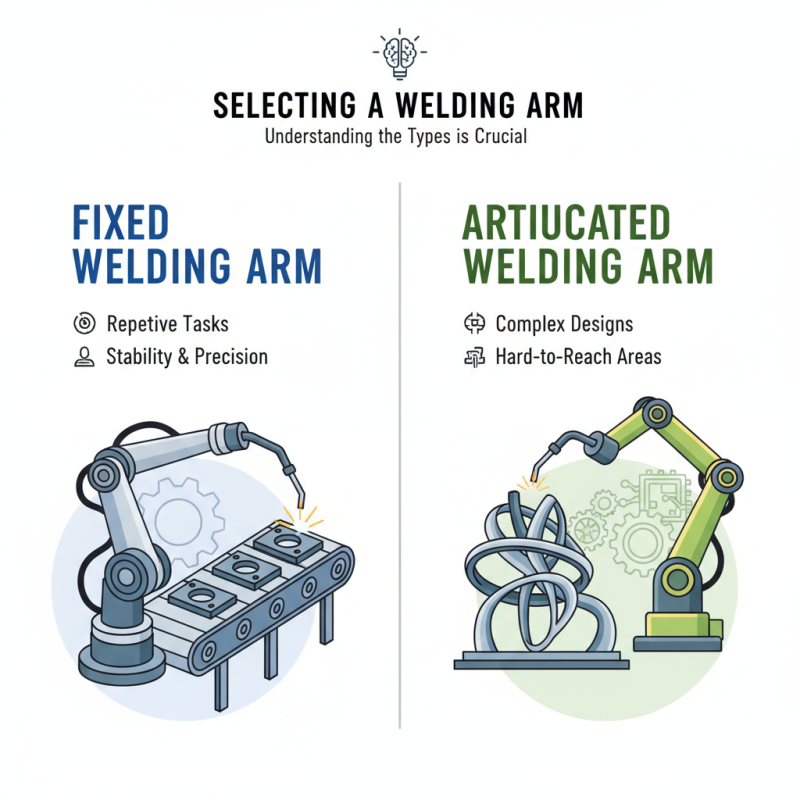

Choosing the right welding arm for your project can significantly impact your results. The welding arm is a critical tool in various industries, including automotive and construction. According to a report by the American Welding Society, nearly 60% of welding failures are due to improper equipment selection. This underlines the importance of making informed decisions when selecting a welding arm.

Expert John Smith, a seasoned welding engineer, emphasizes, "Selecting the right welding arm is crucial for achieving precision." His insights remind us that overlooking this detail can lead to costly mistakes. Many welders struggle with this choice, falling prey to flashy marketing rather than focusing on genuine specifications.

Understanding the types of welding arms available is essential. Features like reach, load capacity, and ease of use should be carefully considered. Rushing through the selection process may result in subpar performance. A welding arm that suits your needs can enhance productivity and welding quality. Careful evaluation can save you from future regrets.

When selecting a welding arm, understanding the various types is crucial. Each type serves different applications. For instance, a fixed welding arm is perfect for repetitive tasks. It offers stability and precision. On the other hand, an articulated arm provides more flexibility. This is beneficial for complex designs and hard-to-reach areas.

Tips: Consider the weight of your materials. A heavier load may require a sturdier arm. Evaluate your workspace too. Tight spaces can limit your options. Don’t overlook the ease of use. Sometimes, a more complex arm can complicate simple tasks.

Additionally, think about the materials you'll be working with. Some arms are better suited for specific welding processes. Be ready to adapt your choice based on your project needs. Understanding these differences can greatly impact your final outcome. Mistakes can happen if you don't consider these factors. Reflect on the effectiveness of your choice as you move forward.

When selecting a welding arm, assessing the weight capacity and reach is crucial. The right choice directly impacts the efficiency of your project. According to industry data, many welding arms have a typical weight capacity ranging from 500 to 2,000 pounds. Understanding your workload helps determine the necessary strength. Overloading a welding arm can lead to accidents and equipment failure.

Reach is another vital factor. Most welding arms offer a reach of 5 to 10 feet. Longer reach enables more versatility. However, it can affect stability and control. Projects with tight spaces may require shorter arms for precision. Adjustability is essential too, as fixed arms limit flexibility in different tasks.

Consider the workpieces involved. Heavy materials may need stronger arms to handle them safely. Not considering these aspects risks inefficiency and potential risks. Survey reports indicate that improper selection often leads to project delays and unforeseen costs. Always weigh your options carefully before deciding.

When selecting a welding arm, the material is crucial. Steel, aluminum, and composite materials each have unique properties. Steel offers strength but can be heavy. Aluminum is lighter but may lack the same durability. Composites provide flexibility but might not withstand high temperatures.

Tips: Consider the environment where you'll use the welding arm. If working outdoors, ensure materials resist corrosion. For high-temperature projects, check for heat-resistant options.

Assess how often you'll use the welding arm. Frequent use demands robust materials. Look for arms with wear-resistant coatings. This choice increases lifespan but may add cost. Don’t overlook ease of maintenance, either. Some materials collect dirt, which can affect performance.

Tips: Test the welding arm if possible. Feel its weight and balance. A comfortable grip can enhance your control. Remember that the right choice will make your projects smoother. Maintain awareness of wear and tear over time. The wrong material can lead to frustration and reduced efficiency.

Choosing a welding arm is not easy. Many factors influence your decision. It's essential to compare pricing and features before making a purchase. Leading brands offer different options, each with its strengths.

Look for the arm's weight capacity. Some models handle heavier materials while others are more lightweight. It’s critical to pick one that matches your project requirements. The price can vary widely. High-end models can be costly, but they may provide added longevity and efficiency.

Tips: Always consider your budget before diving into purchases. Sometimes, cheaper models lack essential features. Research the common issues users have reported. If several reviews mention malfunctions, think twice before buying. Make a list of must-have features before shopping. This will help streamline your choices and avoid impulse buys. Consider renting if unsure about your needs. This option can save costs and let you evaluate different models.

When selecting a welding arm, safety standards cannot be overlooked. The American National Standards Institute (ANSI) emphasizes the need for compliance with safety guidelines. Welding arms must adhere to these standards to protect users effectively. OSHA reports indicate that many welding injuries stem from improper equipment use. This highlights the importance of choosing a compliant welding arm.

Understanding specific safety features is crucial. For instance, the welding arm should have proper shielding. This reduces exposure to harmful fumes and UV radiation. A recent industry survey revealed that nearly 60% of welders reported experiencing respiratory issues linked to inadequate protection. Additionally, ergonomic design is essential. Poor posture during welding can lead to long-term musculoskeletal disorders. Design flaws often lead to discomfort and reduced efficiency.

It's also important to consider variations in industry standards across regions. While some countries have strict compliance rules, others may lack enforcement. This inconsistency can result in welding arms that don’t meet safety requirements. Regular audits of safety compliance in workplaces can help identify gaps. Ignoring these aspects leads to potential hazards. A reflective approach must be taken to ensure the safety of welders and minimize risks.

| Welding Arm Type | Weight Capacity (lbs) | Reach (inches) | Material | Safety Rating | Compliance Standards |

|---|---|---|---|---|---|

| Robot Arm A | 300 | 60 | Aluminum | ISO 9001 | ANSI Z49.1 |

| Manual Arm B | 250 | 50 | Steel | EN ISO 3834 | AWS D1.1 |

| Hybrid Arm C | 400 | 70 | Carbon Fiber | ASME Compliance | ISO 15085 |

| Articulating Arm D | 350 | 65 | Stainless Steel | CE Marked | UL Listed |