Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

In the rapidly evolving landscape of industrial automation, the adoption of automatic welding robots has become an essential strategy for manufacturers aiming to enhance productivity and maintain competitive advantage. According to a recent report by MarketsandMarkets, the global robotic welding market is projected to reach USD 7.12 billion by 2026, growing at a CAGR of 11.5% from 2021. This growth is driven by the increasing demand for automated solutions that not only reduce labor costs but also improve weld quality and consistency.

When considering the integration of an automatic welding robot into production lines, businesses must navigate a multitude of options tailored to various applications and industry needs. Key factors such as the type of materials to be welded, production volume requirements, and workspace layout play crucial roles in determining the optimal choice. Furthermore, advancements in technology have introduced innovative features in modern welding robots, making it imperative for decision-makers to stay informed about the latest developments and potential return on investment.

In this context, understanding the critical aspects of selecting the right automatic welding robot becomes paramount. This guide aims to provide insights and practical tips that will equip businesses with the knowledge necessary to make informed decisions, ultimately leading to enhanced operational efficiency and significant cost savings.

Choosing the right automatic welding robot for your business begins with a deep understanding of your specific needs. Each welding application has unique requirements, such as joint configuration, material types, and production volume. Consider whether you need a robot for high-speed production or one that can handle more intricate, low-volume tasks. Evaluating your existing workflow can also reveal areas where automation can enhance efficiency and reduce overhead costs.

Next, it's essential to assess the scalability of the welding solution. Your business needs may evolve over time, so investing in a robot that can adapt to future projects is crucial. Look for models that offer flexibility in programming and can accommodate various welding techniques, such as MIG, TIG, or flux-cored welding. Additionally, considering the ease of integration with your current systems can significantly impact your decision. A seamless transition to automated welding will not only maximize productivity but also ensure that you fully leverage the capabilities of the chosen equipment.

When selecting the right automatic welding robot for your business, assessing the technical specifications is crucial. Start by examining the welding process types the robot supports—TIG, MIG, or arc welding. Each method has its own advantages and is suitable for different materials and applications. Understanding this will ensure that the chosen robot aligns with your specific production needs.

Another critical factor is the robot's payload capacity and reach. This specification determines the weight the robot can handle and the distance it can effectively operate. Evaluate the size and weight of the components to be welded, as well as the required workspace dimensions. This assessment helps to avoid misalignments and inefficiencies during the welding process.

Lastly, consider the programming options available. User-friendly software that provides intuitive programming tools can significantly reduce setup time and enhance productivity. Look for robots with flexible programming capabilities, allowing for easy adjustments as your welding tasks evolve. By focusing on these technical specifications, you can select an automatic welding robot that not only meets your current needs but also adapts to future demands.

When it comes to selecting the right automatic welding robot for your business, it's essential to compare different brands and models to find one that meets your specific needs. One of the primary factors to consider is the technology used in the robot. Recent advancements have introduced various technologies in automatic welding, including laser and structured light systems. Understanding the strengths and weaknesses of these technologies can significantly impact the efficiency and quality of your welding processes.

Additionally, you should evaluate the performance of different models under various applications. For instance, in high-volume production environments, a robot's adaptability and speed become crucial. Look for models that have been tested for robust performance in similar applications, especially in industries like electric vehicle manufacturing, where welding quality is fundamental to product success.

Here are a few tips: First, assess your business’s specific welding requirements, including joint types and production scale. Secondly, consider the brand's support and service options, as reliable after-sales service can save you time and money in the long run. Lastly, keep an eye on emerging technologies that can enhance the capabilities of welding robots, ensuring your investment remains relevant in a rapidly evolving market.

When selecting an automatic welding robot for your business, evaluating the support and maintenance services of the equipment is crucial. According to a recent industry report by the Robotics Industries Association, companies that invest in robust maintenance programs for their robotic systems report up to a 30% increase in productivity due to reduced downtime. Therefore, understanding the level and accessibility of support services can significantly impact the efficiency of your operations.

Additionally, it's essential to consider the availability of spare parts and technical support. A survey conducted by the International Federation of Robotics revealed that 75% of manufacturers prioritize suppliers who offer comprehensive after-sales support, including 24/7 customer service and rapid response times to technical issues. This kind of reliable support not only ensures that your operations run smoothly but also extends the lifespan of your welding equipment, maximizing your return on investment. Ensuring that the welding robot you choose comes with strong support and maintenance services will be a significant factor in your long-term success.

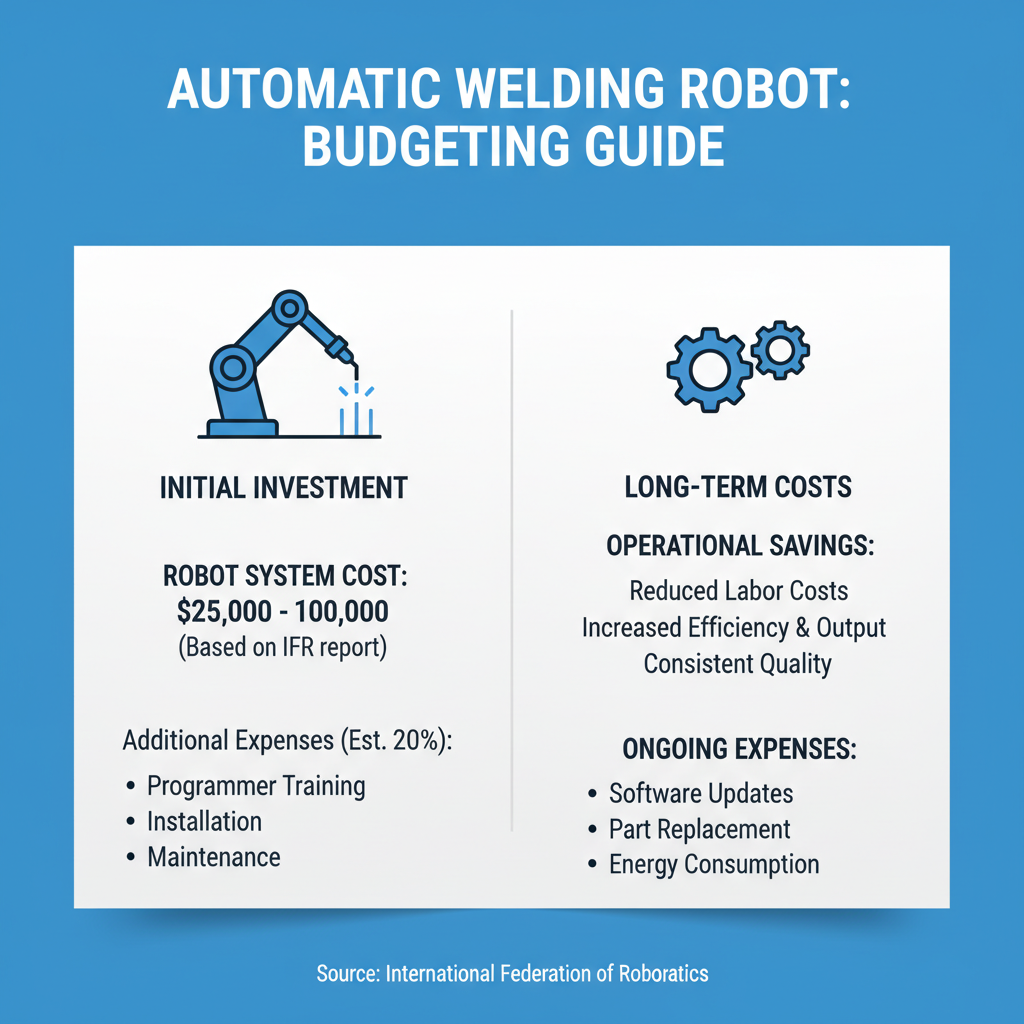

When considering the integration of automatic welding robots into your business operations, understanding the budgeting dynamics for both initial investments and long-term costs is crucial. According to a report by the International Federation of Robotics, the average cost of a welding robot system can range from $25,000 to $100,000, depending on specifications and features. Smaller businesses should prepare for additional expenses such as programmer training, installation, and maintenance, which can add an estimated 20% to the overall budget.

In the long run, these robots can significantly reduce labor costs and increase productivity—often improving precision and reducing material waste. Industry data indicates that companies that adopt automation can see a return on investment (ROI) within 18 to 24 months. However, it’s essential to consider ongoing operational costs, including energy consumption, periodic maintenance (which can average around $1,000 to $3,000 annually), and software updates. A detailed cost analysis, factoring in potential savings and productivity gains, is an indispensable step in evaluating the financial viability of procuring welding robots.