Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

When it comes to maximizing efficiency and precision in welding projects, selecting the right welding arm is crucial. According to renowned welding expert Robert Smith, "The right welding arm can transform a challenging project into a streamlined process, enhancing both quality and speed." With various options available, choosing the best welding arm tailored to your specific needs can significantly impact your overall productivity and results.

In the world of welding, the significance of the welding arm cannot be overstated. A carefully chosen welding arm not only increases ergonomic comfort but also ensures precise control over your work. As many professionals know, the success of a welding project often hinges on this fundamental tool. In this guide, we will explore the top ten tips for selecting the most suitable welding arm for your projects, helping you make an informed choice that aligns with your welding requirements and aspirations.

When selecting a welding arm for your projects, it is essential to understand the various types available on the market. Welding arms are typically categorized based on their applications, such as robotic welding arms, manual welding arms, and positioners. Robotic welding arms are increasingly popular due to their capability to enhance productivity and accuracy. According to a report by MarketsandMarkets, the robotic welding market is expected to grow from $3.2 billion in 2020 to $5.7 billion by 2025, highlighting a significant demand for automation in the welding industry.

In contrast, manual welding arms offer more control and flexibility for specialized tasks, making them ideal for intricate work or for users needing a hands-on approach. Additionally, adjustable welding positioners allow for better access to weld joints at various angles, enhancing technique and reducing fatigue. A survey released by the American Welding Society indicated that 72% of professionals rated maneuverability and adjustment capabilities among the top criteria when selecting welding equipment. Understanding these distinctions is crucial as they directly impact the efficiency and outcome of your welding projects. By carefully considering the type of welding arm that aligns with your specific needs, you can optimize your operational workflow and ensure high-quality results.

When it comes to selecting the best welding arm for your projects, understanding the weight capacity of the arms is vital. Welding arms are designed to handle specific loads, and exceeding this capacity can result in equipment failure and pose safety risks. According to the American Welding Society, the efficiency of welding operations can significantly decrease if the equipment is not adequately suited for the task.

For example, a welding arm with a weight capacity of around 150 pounds is recommended for moderate fabrication tasks, while more intensive projects may require arms that can handle loads in excess of 300 pounds.

Evaluating the weight capacity involves not only the maximum load the arm can support but also the distribution of that weight. An effective welding arm should maintain stability and precision even under heavy loads. Industry research indicates that a well-balanced arm can improve the welding process's overall safety and quality.

Furthermore, considering additional factors such as the arm's range of motion and joint design can help in making a more informed decision. Selecting a welding arm that meets your project's weight capacity requirements ensures both the longevity of the equipment and the safety of the operator.

When selecting the best welding arm for your projects, the reach and flexibility of the arm are paramount. A welding arm with an extended reach allows the welder to access hard-to-reach areas, making it ideal for intricate projects or those that require precision. The length of the arm can significantly affect the efficiency of the welding operation, as it reduces the need for repositioning the workpiece or the arm itself. Ensuring that the reach is appropriate for your specific needs can lead to a smoother workflow and better outcomes.

Flexibility is equally essential, as it allows the welding arm to maneuver easily across various angles and positions. A highly flexible arm can adapt to the shapes and contours of the materials being welded, enhancing the ability to perform different types of welds. Whether working on flat surfaces or rounded profiles, a versatile welding arm can make complex projects much more manageable. Look for features such as adjustable joints or a multi-axis design to optimize the flexibility of the arm, allowing for a greater range of motion and improved control during the welding process.

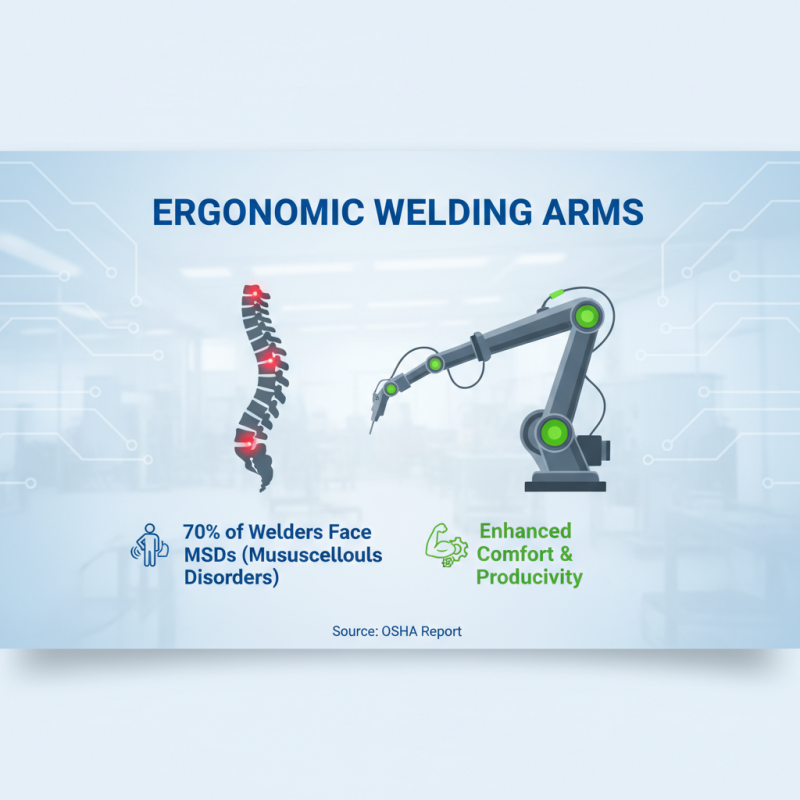

When selecting a welding arm for your projects, it's essential to prioritize ergonomic features that enhance comfort and productivity. According to a report from the Occupational Health and Safety Administration (OSHA), nearly 70% of welders experience musculoskeletal disorders due to poor posture and repetitive strain. As such, choosing a welding arm designed with ergonomics in mind is crucial for long-term health and performance.

Key ergonomic features to consider include adjustable height settings, a lightweight design, and padded handles that reduce strain on the hands and wrists. Studies indicate that tools designed with adjustable parameters can significantly decrease the risk of injury. A survey conducted by the American Welding Society found that 58% of welders reported reduced fatigue and discomfort when using ergonomically designed equipment. Additionally, welding arms that offer increased flexibility can minimize the need for awkward body positioning, further decreasing physical strain over extended periods of use.

Investing in an ergonomic welding arm not only enhances comfort but also boosts efficiency in welding projects. The National Institute for Occupational Safety and Health (NIOSH) emphasizes that improved ergonomic design can lead to a more engaged workforce and reduced absenteeism due to injury. Therefore, understanding the importance of ergonomic features can play a pivotal role in maximizing both your performance and well-being as a welder.

When selecting a welding arm, one of the most critical factors is ensuring compatibility with your existing welding equipment and accessories. A 2022 report from the American Welding Society indicated that nearly 60% of welding failures can be traced back to equipment incompatibility. It is essential to match the welding arm’s specifications—such as weight capacity, reach, and control capabilities—with your welding machine and tools. For instance, if your welding machine operates at a specific amperage, the arm must support that output without strain to maintain efficient operation and safety.

Additionally, considering the types of welding accessories you use is vital. Various tasks require different accessories, like torches and clamps, which must be compatible with the arm’s design and functionalities. A survey from Welding Journal revealed that users who prioritize compatibility report a 25% decrease in setup time and a 30% increase in overall project efficiency. Therefore, take the time to assess how the welding arm aligns with your current setup, including any specific tasks or projects you commonly undertake. Proper compatibility not only enhances performance but also prolongs the lifespan of your equipment.

| Tip No. | Tip Description | Compatibility Tips | Accessories to Consider |

|---|---|---|---|

| 1 | Determine the type of welding projects you'll be working on. | Ensure compatibility with MIG, TIG, or Stick welding. | Check for suitable wire feed systems. |

| 2 | Check the reach of the welding arm. | Ensure the arm can accommodate larger workpieces. | Consider extensions or attachments. |

| 3 | Assess the weight capacity of the arm. | Balance load capacity with your project requirements. | Utilize clamping tools for heavy materials. |

| 4 | Look for adjustable features for precision. | Adjust settings to match your welding style. | Select jigs or fixtures for accurate alignment. |

| 5 | Evaluate ease of operation and control. | Consider remote controls or automation options. | Use foot pedals for hands-free operation. |

| 6 | Examine the material quality of the welding arm. | Choose sturdy materials like aluminum or steel. | Consider protective covers for durability. |

| 7 | Research user feedback and reviews. | Look for consistency in reliability and performance. | Join forums for community insights on best practices. |

| 8 | Consider the cost-effectiveness of the welding arm. | Balance between price and features offered. | Review ongoing maintenance costs of accessories. |

| 9 | Check for warranty and service options. | Ensure reliable customer support is available. | Consider extended warranties for peace of mind. |

| 10 | Test different models if possible. | Find the best fit for your body mechanics and style. | Use demo models to evaluate performance. |