Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

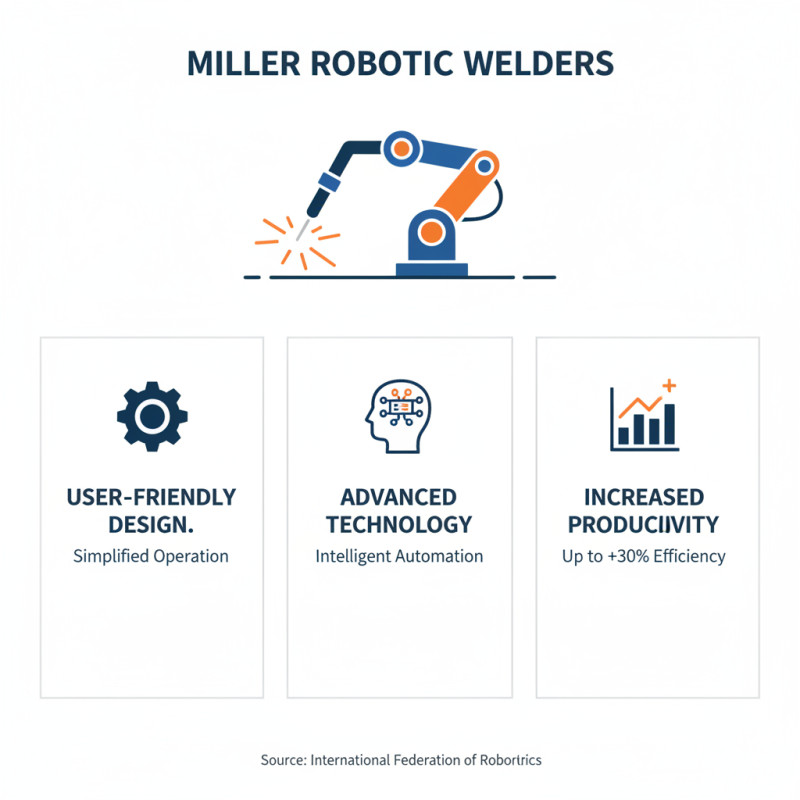

In today's competitive manufacturing landscape, choosing the right welding technology is crucial. The Miller Robotic Welder stands out due to its precision and efficiency. According to industry reports by the American Welding Society, automated welding can increase productivity by up to 30%. This statistic highlights the importance of investing in advanced solutions like the miller robotic welder.

John Smith, a renowned welding technology expert, emphasizes, “Automation is not just a choice; it’s the future of welding.” This statement reflects the shift many manufacturers are making towards robotic solutions. As industries evolve, seeking enhanced productivity and quality becomes essential.

The Miller Robotic Welder brings reliability and scalability to welding operations. However, many companies struggle with the transition. They may find the initial costs daunting. Investing in automation requires careful consideration and planning. Yet, the long-term benefits can outweigh these challenges, providing a clear path toward growth and efficiency.

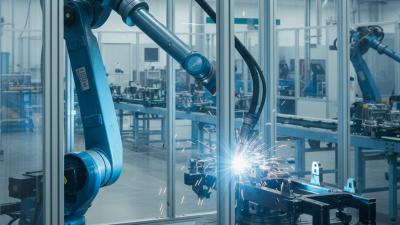

Robotic welders are transforming various industries with their efficiency and precision. These machines handle repetitive tasks quickly, ensuring consistent quality in every weld. The reduced labor cost is appealing for many businesses. However, the initial investment can be daunting for some.

In manufacturing, robotic welding eliminates human error. The intricacies involved in joint preparation and alignment are managed with exact precision. This leads to a significant decrease in rework and waste. Yet, programming these machines requires skilled personnel. Investing in training can be a hurdle for smaller operations.

Automotive and aerospace sectors benefit greatly from automation. Robotic welders streamline production lines, increasing output significantly. However, downtime due to maintenance can disrupt workflows. Finding a balance between efficiency and reliability is crucial for sustained success. Overall, while robotic welding presents substantial benefits, there are challenges that companies must navigate carefully.

Miller robotic welding systems stand out due to their advanced technology. These systems feature cutting-edge automation tools. They improve efficiency and precision in welding tasks. Automated welders can operate at high speeds, reducing production time. This means less waiting and more output.

The technology behind these systems includes precision sensors and advanced software. Sensors help in monitoring joint integrity in real-time. This reduces the risk of mistakes during the welding process. However, operation can be complex. Training is essential to fully utilize the systems. Without proper training, operators may struggle with adjustments.

Feedback loops in the systems offer enhanced control, but they are also a double-edged sword. Sometimes, over-reliance on technology can lead to oversight. Operators may miss subtle errors. Regular assessments are crucial to maintaining quality. Mistakes in setup can result in wasted materials and time. Ultimately, while the technology is impressive, human expertise remains invaluable.

When considering robotic welding solutions, cost efficiency is often a primary concern. Imagine a manufacturing facility operating with outdated methods. Labor costs can skyrocket, and production speed may lag. By implementing robotic welders, companies can see significant savings in labor expenses. These machines require less human oversight and can work through the night. The initial investment might seem daunting, but the long-term savings are hard to ignore.

Energy consumption is another critical factor. Robotic welders optimize their energy use far better than manual processes. They reduce wasted time and materials. This efficiency leads to lower operational costs. However, the transition is not always smooth. Some may find it challenging to adapt to new technology. Training is necessary, and some workers may resist. Reflecting on these challenges is essential before making a switch.

Quality control also plays a role in cost savings. Robotic welders provide consistent results, minimizing the risk of errors. Defects can lead to waste, impacting overall production costs. While robotic systems can enhance precision, occasional glitches do occur. Addressing these issues can require additional resources, prompting companies to evaluate their specific needs. Balancing the benefits and challenges is key to understanding the true cost efficiency of robotic welding solutions.

Miller robotic welders are designed with user-friendly features that greatly enhance the welding process. These welders often integrate advanced technology to simplify operation. A report by the International Federation of Robotics shows that automation can increase productivity by up to 30%. This is significant for businesses aiming for efficiency.

The intuitive interface is a standout feature. Operators can quickly learn to navigate it, reducing training time. Studies indicate that user-friendly machines decrease the likelihood of errors, which is crucial in welding. Welding defects can cost companies millions, so having reliable equipment is essential.

Furthermore, many modern robotic welders offer real-time monitoring. This allows operators to catch issues before they escalate. The ability to adjust settings on the fly can prevent waste of materials. However, adding complex features can sometimes lead to confusion. It's important for operators to understand each function fully. The balance between sophistication and usability is vital in maximizing benefits without overwhelming users.

When considering welding technology, versatility is key. Various industries can benefit from advanced welding solutions. Manufacturing, automotive, aerospace, and construction each have distinct needs.

A robotic welder adapts easily. It handles complex shapes and materials with precision. This flexibility leads to improved production rates. Workers can focus on finer details, while robots handle repetitive tasks.

In the automotive sector, welding is crucial. Robotic welders ensure consistent joining of parts. Even in tight spaces, they perform effectively. In aerospace, precision is non-negotiable. Every weld must meet stringent safety standards. Here, robotic technology shines. It reduces human error and enhances structural integrity. Many manufacturers see a decline in defects, leading to better products.

Reflections arise when using automation. Not every task is suited for robots. Some intricate designs still require human touch. Additionally, initial setup may be time-intensive. Training staff for operation is essential. Balancing automation with skilled labor is vital. With the right approach, industries discover the true potential of robotic welders.