Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

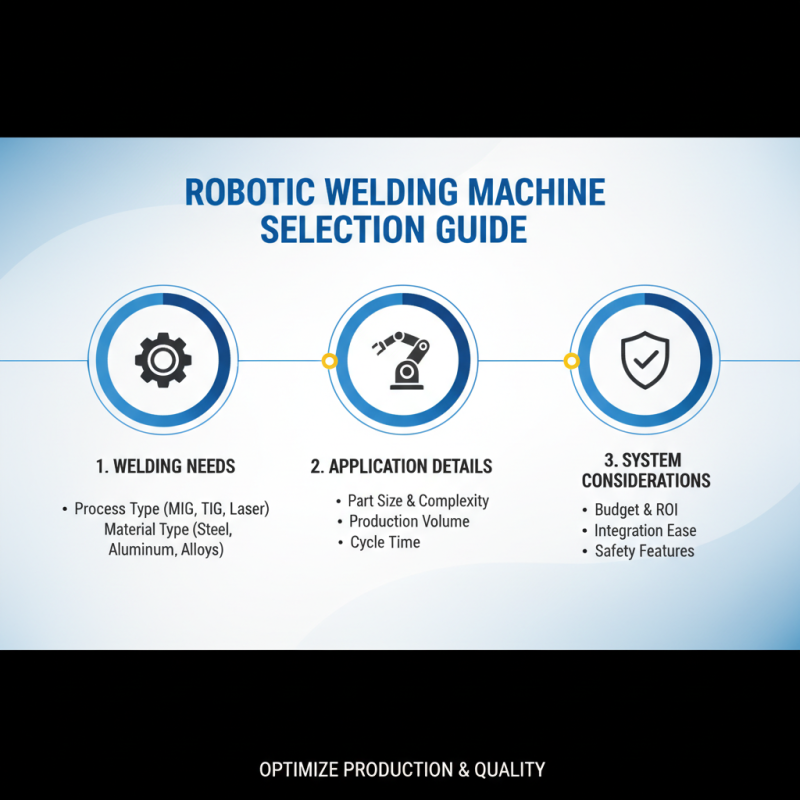

In today's manufacturing landscape, choosing the right robotic welding machine is critical. As industry expert John Miller states, “The right machine can transform your production line.” This insight highlights the importance of understanding your specific needs before making a purchase.

Robotic welding machines vary in capabilities, features, and costs. With options ranging from high-speed welders to those designed for intricate tasks, it's essential to assess what fits your production requirements best. Factors such as welding type, material compatibility, and machine versatility play a significant role in this decision.

Yet, many companies overlook key considerations. It's easy to get lost in brand hype or flashy features. Sometimes, the best choice isn't the most expensive one. Evaluating your production environment and workflow is essential. Take the time to reflect on these details; they can lead to smarter decisions and better outcomes.

In 2026, the range of robotic welding machines has expanded significantly. Many choices exist based on specific tasks. Some machines excel in MIG welding, while others are tailored for TIG welding. It's crucial to identify the type that aligns with your projects. Opt for machines designed for the materials you'll be working with, whether it's steel, aluminum, or other metals.

Consider the complexity of the tasks at hand. Some robotic welders feature advanced programming capabilities. They can adapt to different welding paths and parameters with ease. However, more sophisticated machines often come with a learning curve. Training operators can be time-consuming. You might find it challenging to maximize the machine's potential without thorough understanding.

Pay attention to the machine's payload capacity. Heavier items require robust systems. If you're dealing with large components, ensure the robot can handle them efficiently. Choosing the wrong machine can lead to frustrations and inefficiencies. Evaluate your production needs and consider future expansions, as it can be a significant investment.

Selecting a robotic welding machine requires examining several key factors. The first consideration is your specific welding needs. Different projects require different welding processes. Think about the materials you will be working with. Aluminum, steel, and others require different approaches.

Tips: Review past projects to see what worked and what didn’t. This can provide insights into your future needs.

Another important factor is the machine's speed and precision. A faster machine can increase production, but accuracy remains critical. Sometimes, faster isn’t always better. A less precise weld could lead to rework or less integrity in the final product.

Tips: Test the machine before purchasing. This step may help you gauge its performance in real-world applications.

Consider the ease of use and programming. Machines with complex interfaces can slow down your operations. Look for intuitive controls that your team can quickly learn. Training time is an investment in productivity.

Tips: Engage your team when evaluating machines. Their hands-on experience can offer valuable perspectives.

When selecting a robotic welding machine, evaluating technical specifications is crucial. Speed is a primary factor. Faster machines improve productivity and reduce cycle times. However, higher speed may sometimes compromise weld quality. Striking the right balance is essential. A machine that operates too quickly could produce inconsistent results, leading to costly reworks.

Precision is another key consideration. Inaccurate welds can be detrimental, especially in critical applications. Machines with advanced software and sensors often provide better control over welding parameters. Nonetheless, using high precision equipment can be complex. Operators must be well-trained to handle these systems effectively. In some cases, a machine that seems perfect on paper may not deliver the expected results in real-world settings.

Flexibility plays a significant role too. A machine that can handle various materials and weld types adds value. This versatility can lead to more efficient production processes. However, flexibility may come at the cost of speed or precision. It’s important to reflect on the specific needs of your operations. Ultimately, choosing a robotic welding machine requires careful consideration of these technical aspects.

| Specification | Option 1 | Option 2 | Option 3 |

|---|---|---|---|

| Maximum Speed (m/min) | 12 | 15 | 10 |

| Precision (mm) | 0.02 | 0.01 | 0.05 |

| Payload Capacity (kg) | 100 | 150 | 75 |

| Axis of Movement | 6 | 7 | 5 |

| Flexibility (Workpiece Types) | High | Moderate | Low |

When considering a robotic welding machine, cost analysis is crucial. You need to budget for the initial investment, which can be significant. Many models are pricey, but cheaper options may lack essential features. So, finding a middle ground is essential. Calculate not just the purchase price but also installation costs. Don't underestimate the training expenses as well. Each of these elements adds to the total upfront cost.

Long-term maintenance is another critical factor. Consider the warranty period and the cost of replacement parts. Regular maintenance checks are important, but they can add up over time. Evaluate the availability of local service providers to avoid long downtimes. Some machines may require specialized technicians, increasing potential expenses. A machine that seems affordable may result in higher costs later. Reflecting on these costs can make a significant difference in your decision.

When selecting a robotic welding machine, consider your specific industry applications. Different sectors have unique requirements. For example, automotive manufacturing demands precision and speed. Conversely, construction might prioritize versatility and ruggedness. Understanding your needs is crucial.

Tip: Evaluate the types of materials you work with. Some machines excel with certain metals but struggle with others. Identify the thickness and alloy types involved in your projects. This will guide you in choosing the right machine.

Keep in mind that certain machines may not perform optimally under all conditions. Be aware of the limitations of potential choices. Assess their adaptability to varied tasks. An initial investment might seem high, but the long-term savings in efficiency can be significant.

Tip: Don't forget about the support and training provided. A user-friendly interface can make a big difference. Lack of proper training could lead to mistakes and inefficiencies. Always consider the learning curve alongside your machine's capabilities.