Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

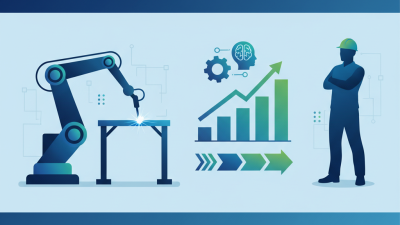

In the rapidly evolving landscape of manufacturing, the shift towards automated welding solutions has become a pivotal focus for businesses seeking to enhance efficiency and product quality. As noted by industry expert Dr. Jane Smith, “The integration of automated welding solutions not only streamlines production but also significantly minimizes the risks of human error, leading to superior weld integrity.” This sentiment underscores the importance of selecting the right automated systems to meet specific operational needs.

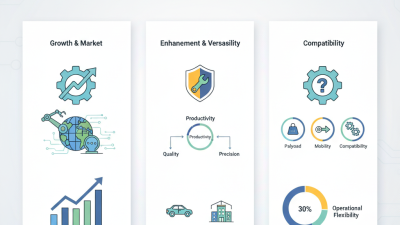

As companies strive for greater competitiveness, understanding how to choose the right automated welding solutions can make a significant difference. Factors such as the types of materials being welded, the complexity of the welding tasks, and the production volume are critical considerations that can influence the effectiveness of these automated systems. The right choice can lead to increased throughput, better consistency in quality, and ultimately, higher customer satisfaction.

In this introduction to selecting automated welding solutions, we will explore essential criteria and key trends shaping the industry, providing insights that can empower decision-makers to implement technologies that not only enhance efficiency but also elevate the overall quality of welded products.

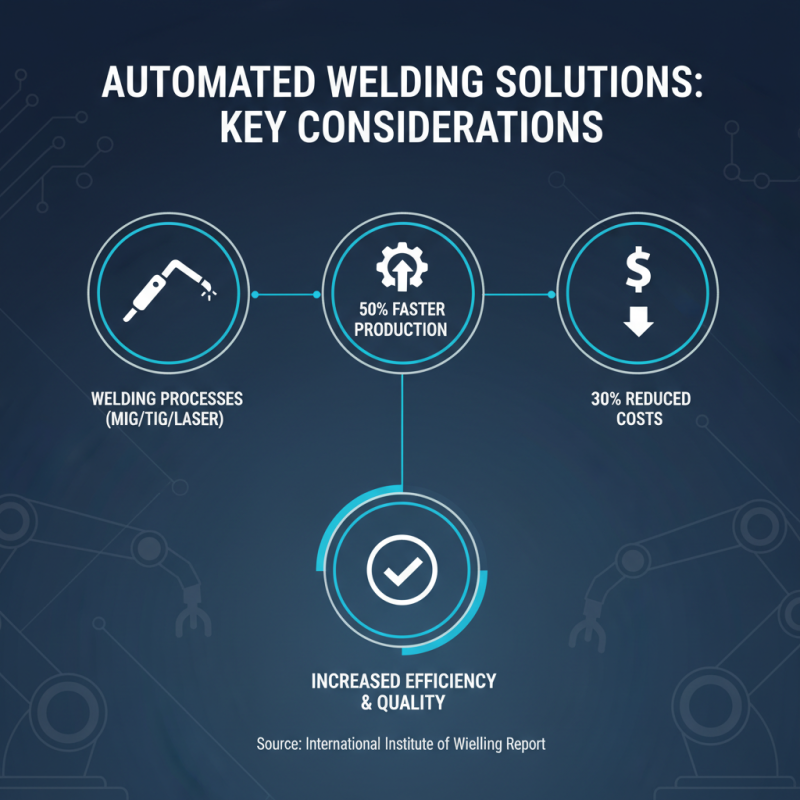

When selecting automated welding solutions, it is crucial to assess several key considerations that can significantly impact efficiency and quality. First, understanding the specific welding processes required for your projects—such as MIG, TIG, or laser welding—is vital. According to a report by the International Institute of Welding, automated welding systems can improve production rates by up to 50% and reduce operational costs by 30% compared to manual welding. This highlights the importance of selecting a solution that matches the technical requirements of your application.

Another critical factor is the technology used in the automated solution. For instance, advancements in artificial intelligence and machine learning have allowed for more sophisticated welding equipment capable of real-time adjustments and monitoring. A study by the American Welding Society found that automation can lead to improvements in weld quality and consistency, resulting in error rates that are 90% lower than manual processes. Therefore, investing in systems with integrated software for quality control can ensure that welds meet industry standards and reduce rework costs.

Lastly, consider the scalability of the solution. As market demands fluctuate, having an automated welding system that can easily adapt to varying production volumes is essential. Data from the Manufacturing Technology Market Research report suggests that businesses with flexible automation strategies have 20% lower costs and a 30% increase in throughput. Therefore, an adaptable welding solution not only meets immediate requirements but also positions a company for future growth.

The landscape of automated welding technologies has evolved significantly, offering diverse solutions tailored to enhance efficiency and quality in various industrial applications. Key types of automated welding technologies include robotic welding systems, laser welding, and friction stir welding.

Robotic welding has gained prominence due to its precision and ability to handle complex geometries, resulting in a 30% increase in productivity as reported by industry analysts. This technology allows manufacturers to automate repetitive tasks, reduce human error, and improve safety on the shop floor.

Laser welding, on the other hand, stands out for its speed and versatility. This method can achieve high-quality welds without the need for extensive post-weld processing. According to a study by the International Institute of Welding, laser welding can enhance joint strength by up to 20% compared to conventional methods while also increasing welding speeds by 50%. Additionally, friction stir welding is notable for its capability to join materials that are otherwise difficult to weld, such as aluminum alloys. Its solid-state approach minimizes distortion and residual stress, making it an attractive option for the automotive and aerospace sectors, where material integrity is paramount.

Understanding these technologies is crucial for manufacturers seeking to invest in automated welding solutions. By selecting the appropriate technology based on production needs and material characteristics, companies can significantly boost efficiency and elevate quality standards across their operations.

When evaluating efficiency metrics in welding automation, it is essential to focus on key performance indicators (KPIs) that directly impact productivity and quality. Metrics such as cycle time, throughput, and defect rates are crucial to understanding the effectiveness of automated welding systems. By analyzing these data points, companies can identify bottlenecks in the welding process and make informed decisions about their automation investments.

**Tips:** Consider implementing a real-time monitoring system to track these KPIs as they occur. This proactive approach can help teams quickly respond to issues and optimize the welding process for better outcomes.

Additionally, comparing the efficiency of various automated welding solutions can provide insights into their relative performance. Look for systems that offer flexibility in settings and compatibility with different materials, as this versatility can significantly enhance overall productivity.

**Tips:** Regular training for personnel on using automation technologies can translate into improved efficiency. Skilled operators are better able to maximize the capabilities of the welding systems, leading to fewer errors and increased output.

Quality control is a critical aspect in the selection of automated welding solutions, as it directly impacts both efficiency and product reliability. According to a report by the American Welding Society, nearly 40% of manufacturing defects stem from inadequate quality control during welding processes. Implementing advanced quality control features, such as real-time monitoring and adaptive feedback loops, can significantly reduce these defects. Automated systems equipped with in-process inspection technologies ensure that welds meet stringent quality standards, thereby minimizing rework and enhancing overall production efficiency.

Moreover, integrating data analytics into welding systems allows for a more comprehensive assessment of weld quality. A study by Research and Markets indicates that leveraging data-driven insights can improve welding accuracy by up to 25%. Automated welding systems with built-in quality assurance measures, such as ultrasonic and x-ray inspection capabilities, provide manufacturers with the tools needed to evaluate weld integrity continuously. By utilizing these advanced features, companies can not only expedite their production processes but also assure clients of the high caliber of their products, leading to increased customer satisfaction and loyalty in a competitive marketplace.

The integration of automated welding solutions with existing manufacturing processes is crucial for organizations seeking to enhance efficiency and quality in their production lines. According to a report by the International Federation of Robotics, the global market for industrial robots, including automated welding systems, is expected to grow at a compound annual growth rate (CAGR) of 10.5% from 2021 to 2028. This growth indicates a robust demand for automation technologies, driven in part by the need to streamline manufacturing processes and improve overall productivity.

To successfully implement automated welding systems, it is essential to conduct a thorough analysis of existing workflows and identify areas where automation can be integrated seamlessly. This might involve retrofitting existing machines with automated features or creating new workflows that complement manual processes. Data from the American Welding Society suggests that automation can increase welding productivity by up to 50%, while reducing defects by as much as 80%. By aligning automated welding solutions with established manufacturing practices, companies can achieve a harmonious balance that maximizes operational efficiency while maintaining high-quality standards.

Furthermore, communication between automated systems and existing machinery is vital for a cohesive workflow. Utilizing advanced software that enables interoperability between different systems can enhance data exchange and streamline operations. Research from the Manufacturing Institute indicates that companies that adopt integrated automation strategies report a 25% reduction in production time, illustrating the potential for significant gains when automated welding solutions are effectively linked with existing manufacturing processes.