Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

In today's fast-paced manufacturing environment, efficiency is paramount. Many businesses are turning to automation to improve production processes. A small welding robot stands out as an ideal solution. These machines offer precision and speed that human workers cannot match.

Small welding robots can easily fit into tight spaces. They are designed to handle various tasks, from simple welds to complex structures. This versatility makes them valuable for businesses of all sizes. They reduce labor costs and increase output. However, integrating a small welding robot does require thoughtful planning.

There are challenges to consider. For instance, the initial investment can be substantial. Training staff to work with these robots also poses a hurdle. Moreover, reliance on technology may lead to potential issues if the machine fails. While the benefits are clear, careful implementation is essential for long-term success.

Small welding robots are gaining popularity in the manufacturing landscape. They offer a range of advantages that cannot be overlooked. For one, these robots can work in tight spaces. This flexibility allows factories to optimize their layouts. Many businesses find that smaller robots can handle various tasks efficiently. They excel in repetitive processes, ensuring consistent quality.

Cost is another key benefit. Smaller welding robots typically require less investment. They consume less energy and generate less waste. This efficiency translates into lower operational costs. However, companies must evaluate their specific needs. Not all applications may suit smaller robots. Sometimes, traditional methods may still be better suited for larger projects.

While the technology is impressive, it isn't without challenges. Programmers might find a learning curve when integrating new systems. Maintenance requires attention and can be time-consuming. Businesses must also consider employee training to ensure smooth operations. Reflecting on these factors can help companies make informed decisions.

| Advantage | Description | Impact on Business |

|---|---|---|

| Precision | Small welding robots offer highly accurate welding capabilities, ensuring consistent quality. | Improves product quality and reduces the rate of defects. |

| Space Efficiency | Their compact size allows them to fit into small workspaces, maximizing floor space. | Allows for better use of factory space and reallocation of resources. |

| Cost-Effective | Lower initial investment and reduced operational costs compared to larger robots. | Makes automation more accessible for small to medium-sized enterprises. |

| Ease of Programming | User-friendly interfaces simplify the programming process for operators. | Reduces training time and increases productivity. |

| Flexibility | Can be quickly reconfigured for different tasks and projects. | Adapts easily to changing production needs. |

| Safety | Reduces human exposure to hazardous welding environments. | Enhances worker safety and minimizes health risks. |

Small welding robots are gaining popularity among businesses. One key reason is their cost-effectiveness. These machines often require a lower initial investment compared to larger industrial models. They use less energy and have lower operational costs. This can lead to significant savings for small and medium enterprises. Moreover, maintenance costs are often reduced due to their simpler design and fewer moving parts.

Small welding robots can increase productivity. They work consistently without breaks, resulting in higher output. However, some companies may overlook the potential training costs. Workers need time to learn how to operate these robots effectively. If not managed well, this could slow down initial production. Investing in quality training can mitigate these challenges.

Adopting small welding robots also improves precision. They can deliver consistent weld quality across projects. Yet, companies should be cautious about their reliance on automation. Some tasks might still require human oversight. Balancing technology and human skill is essential for optimal results.

Small welding robots are gaining traction in various industries.

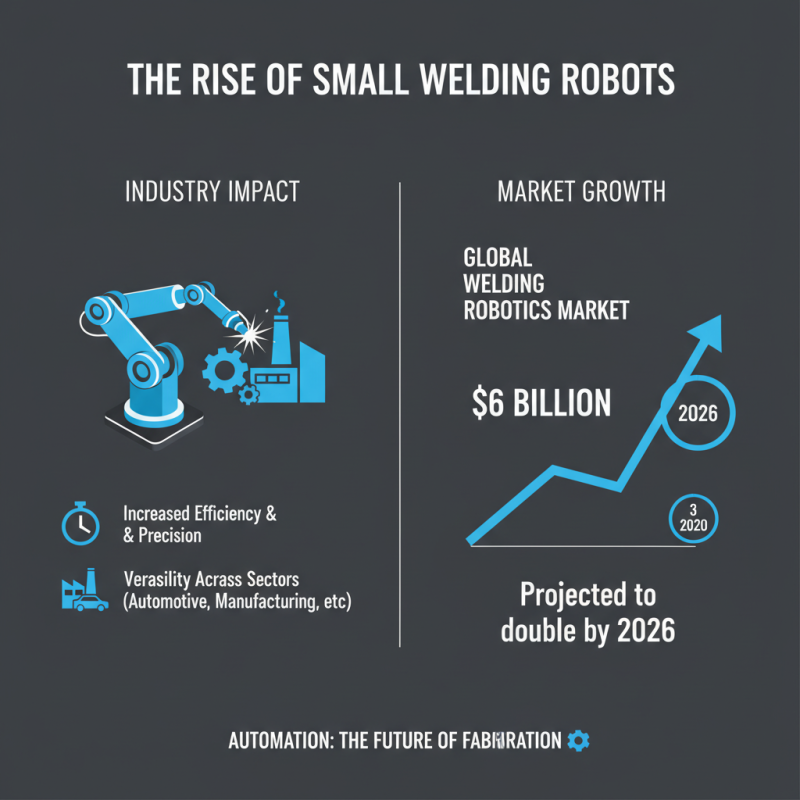

According to a report by Research and Markets, the global welding robots market is projected to grow to $6.96 billion by 2026.

This growth highlights the increasing preference for automation over traditional welding methods.

Traditional processes often rely heavily on manual labor, leading to inconsistent quality and higher labor costs.

On the other hand, small welding robots deliver precise results in shorter timeframes.

These machines can operate continuously without fatigue, reducing the possibility of human error.

A survey by the International Federation of Robotics states that automated welding can increase productivity by 30% compared to traditional methods.

However, implementing such technology can be daunting.

Initial costs may deter some businesses, and the learning curve for staff must be considered.

While the advantages are clear, some manufacturers struggle to adapt.

There might be resistance to changing established practices.

Process integration can also pose challenges, especially for smaller businesses with limited resources.

The effectiveness of small welding robots may vary depending on the specific application.

Proper evaluation is essential to determine if such technology aligns with business goals.

Small welding robots are increasingly popular across various industries. They offer unique advantages in fields like automotive manufacturing and electronics. In the automotive sector, precision is vital. These robots excel in producing high-quality welds for car frames and components. They ensure consistency and reduce errors. However, they may not always handle complex shapes as effectively as larger systems.

In the electronics industry, small welding robots can assemble delicate parts with care. They work on circuit boards, attaching components securely. This is crucial for ensuring device functionality. Despite their ability, programming small robots can be a challenge. Fine-tuning settings for different materials might take additional time.

Small welding robots also find applications in the metalworking sector. They help businesses adapt to varying production requirements. While these robots can improve efficiency, they require monitoring. Human oversight remains essential to address any unexpected issues. Investing in small welding robots can pay off. Yet, companies must weigh the initial costs and potential learning curves.

Small welding robots are gaining traction in various industries. The trend towards automation is impressive. According to a recent report, the global welding robotics market is projected to reach $6 billion by 2026. This growth reflects the increasing efficiency demands faced by businesses today.

Small welding robots can streamline operations significantly. They can reduce labor costs by up to 30%. They also enhance precision, lowering the chances of defects. However, adjusting to these technologies can be challenging. Some businesses may struggle with integrating robots into their workflow. Training staff to work alongside robots requires time and resources, and not all companies are fully prepared for this change.

The future of small welding robots looks bright. Many experts forecast that continued advancements in AI and machine learning will improve these systems. This could lead to greater flexibility and adaptability in production processes. However, it's essential to approach these changes carefully. Companies must invest in proper training and support, ensuring a smooth transition to new technology. It’s not just about investing in robots; it’s about cultivating a culture that embraces innovation.