Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

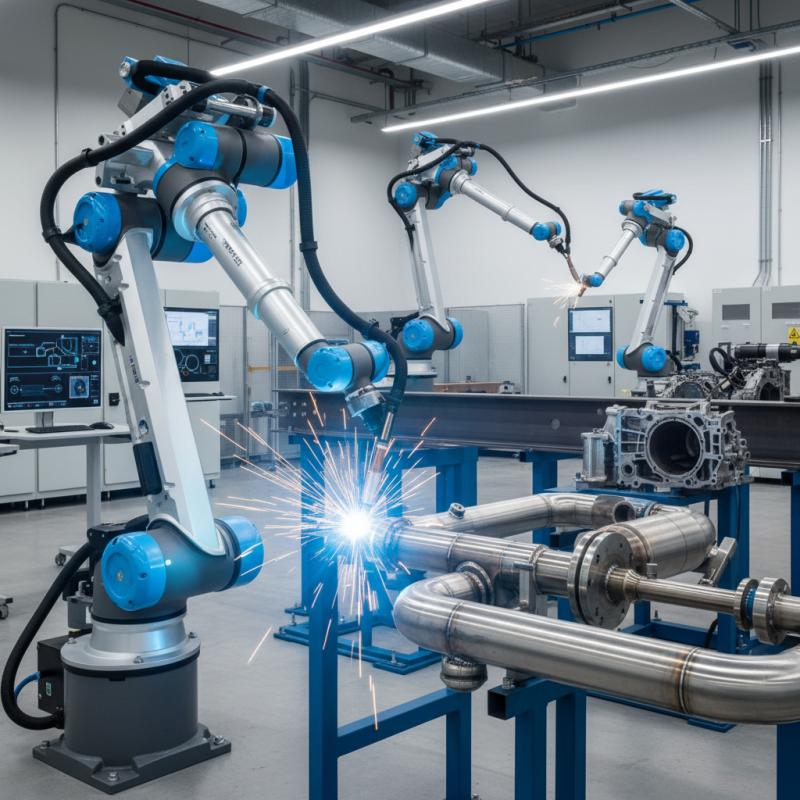

Choosing the right robotic welding arm can significantly impact your business. It’s not just about brand names or price tags. Each business has unique needs that must be met.

When evaluating options, think about your welding tasks. Consider the materials you often use. The type of robotic welding arm needed for stainless steel differs from that for aluminum. Size and weight also matter. A robust arm might work well for heavy fabrication but can be cumbersome in tight spaces.

Budget constraints often push for compromises. However, investing in high-quality technology can enhance productivity. It’s tempting to pick the cheapest model, but this choice may lead to longer-term costs. Reflect on durability, efficiency, and maintenance requirements. Your decision will shape your production line’s future.

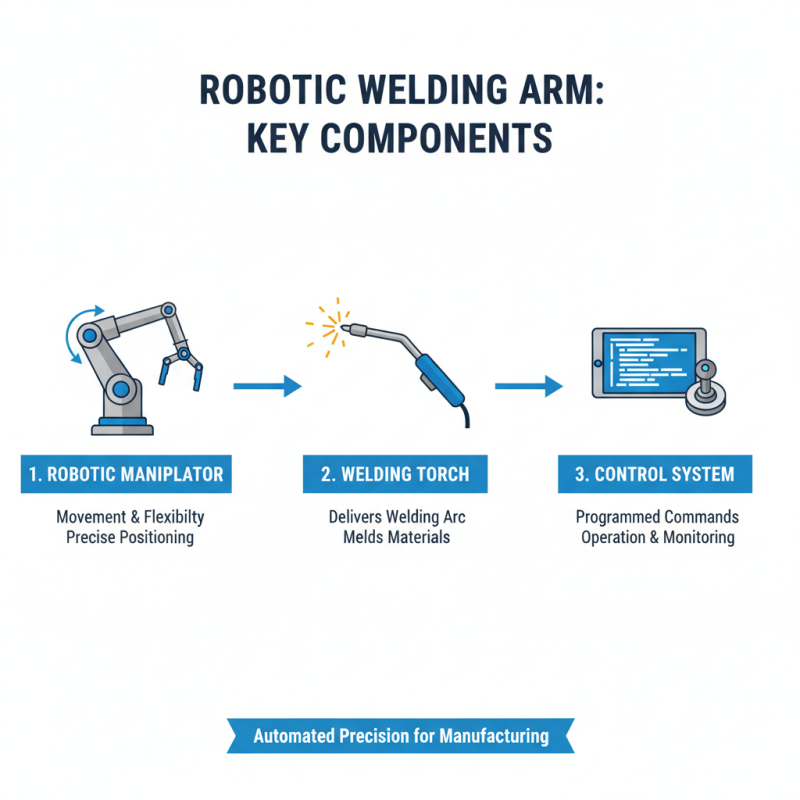

When choosing a robotic welding arm, it's crucial to understand its basic components. A welding arm typically consists of a robotic manipulator, welding torch, and control system. The manipulator provides movement and flexibility, enabling precise positioning. It's like the arm of a skilled worker, but it operates based on programmed commands.

The welding torch is the heart of the process. It delivers heat and filler material to create strong joints. Different applications may require various torch designs. Understanding these options can help in selecting the right torch for specific tasks. The control system is equally important. It governs the entire operation, ensuring accurate movements and settings. A user-friendly interface can make or break the efficiency of the workflow.

Reflecting on these components may reveal gaps in current knowledge or application. For instance, one might overlook the importance of the control system, thinking the arm's design is enough. Testing different setups can be enlightening. It often leads to insights on improving productivity and quality. Each choice impacts the overall performance, so careful consideration is essential.

When selecting a robotic welding arm, understanding your business workflow is vital. Start by examining your current production process. Identify bottlenecks and inefficiencies. Consider the types of materials you work with. Do you primarily use steel, aluminum, or a mix? Each material requires different settings and approaches.

Evaluate the scale of your operations. A high-volume production line may need more advanced technologies. Assess the flexibility you require as well. Can your production line adapt to new designs quickly? Sometimes, scalability leads to bigger issues. Training employees to use new equipment can be challenging. They may struggle to adapt, impacting productivity.

Production requirements will dictate the features you need. Look at cycle times and joint types. Are you welding complex geometries? The robotic arm must be capable of precise movements. Speed is crucial, but accuracy is non-negotiable. Don't overlook maintenance either; some systems require more upkeep than others. Balancing these factors can be tricky, but it's essential for making a well-informed choice.

| Feature | Description | Importance Level |

|---|---|---|

| Payload Capacity | Maximum weight the robot can handle efficiently. | High |

| Reach | Distance the robotic arm can extend to perform welding tasks. | Medium |

| Precision | Accuracy of the welding process, critical for quality control. | High |

| Speed | Rate at which the robot can complete welding tasks. | High |

| Ease of Programming | How user-friendly the programming interface is for setup. | Medium |

| Integration Capability | Ability to work with existing systems and equipment. | High |

| Maintenance Requirements | Frequency and complexity of maintenance needed for optimal operation. | Medium |

| Cost | Total investment required for purchase and operation. | High |

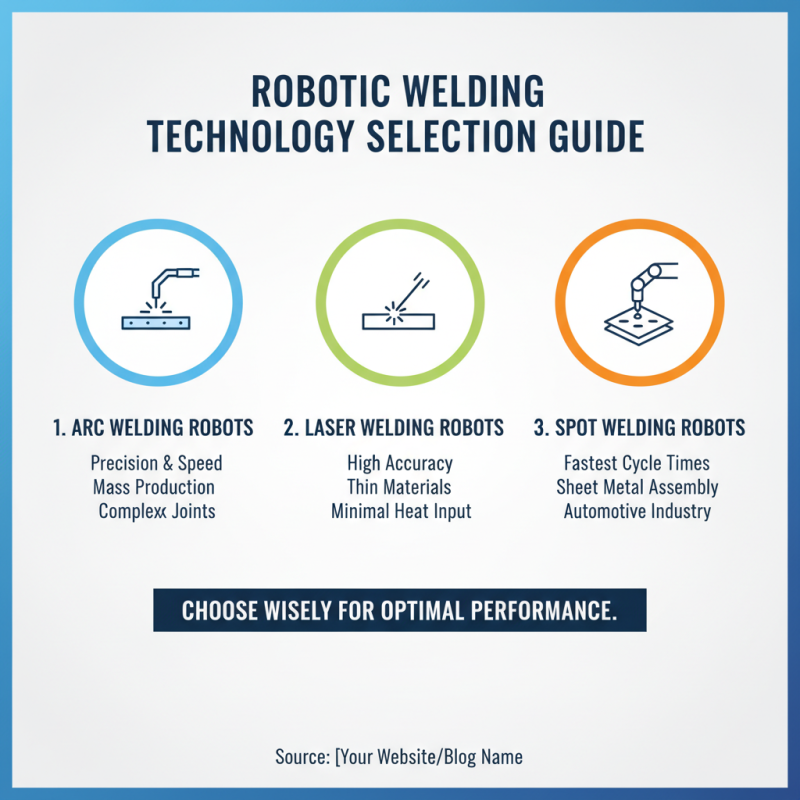

Choosing the right robotic welding technology is critical. Various types are available, each with its unique capabilities. Arc welding robots excel in precision and speed. They perform well in mass production setups and can easily handle complex joint configurations.

Another option is laser welding. This method requires careful consideration. It offers minimal heat input and high-quality welds. However, it also demands a significant investment in equipment and training. Resistance welding is another alternative. It is known for its efficiency in parts assembly. But, it may not suit all materials.

Selecting the most effective technology hinges on your specific needs. Assess the types of materials involved and the complexity of your projects. Traditional methods may need to be reconsidered if they don't meet production goals. Testing different systems can help pinpoint what works best. A careful evaluation today can lead to better decisions tomorrow.

When considering robotic welding solutions, cost is a crucial factor. Businesses often have varying budgets. It’s essential to evaluate each option's upfront cost and long-term expenses. A cheaper model may save money initially but could lead to higher maintenance costs down the road. The hidden costs can quickly add up.

Moreover, think about your specific needs. Some projects might require advanced features, driving up the price. Others may suffice with basic capabilities. Before making a decision, analyze the potential return on investment (ROI). Will the arm improve productivity? Could it reduce labor costs?

Reflect on additional expenses such as training, installation, and software. Sometimes, a higher initial investment yields better results. Consider future scalability. Will this equipment grow with your business? Make a comprehensive budget plan. Don't overlook unexpected costs. Balancing quality and cost needs careful thought.

Determining support and maintenance needs is vital for robotic welding systems. A 2021 industry survey revealed that 70% of companies faced unplanned downtime due to maintenance issues. This affects productivity and can lead to cost overruns. Understanding the complexities of these systems helps in planning effective maintenance strategies.

Regular inspections are essential. A well-maintained robotic arm can achieve up to a 95% operational efficiency rate. However, many businesses overlook this. They often forget that robotic systems need routine calibration and software updates. This oversight can cause performance dips, affecting output quality. Each robot's configuration requires tailored maintenance plans.

Having a support team in place is another critical factor. Technical support can mitigate challenges quickly. Yet, many businesses struggle with inadequate support. The 2022 Robotics Industry Association report indicated 30% of firms still lacked proper maintenance contracts. This gap can lead to increased repair costs and longer downtimes. Companies must reflect on their support infrastructure to optimize robot performance.