Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

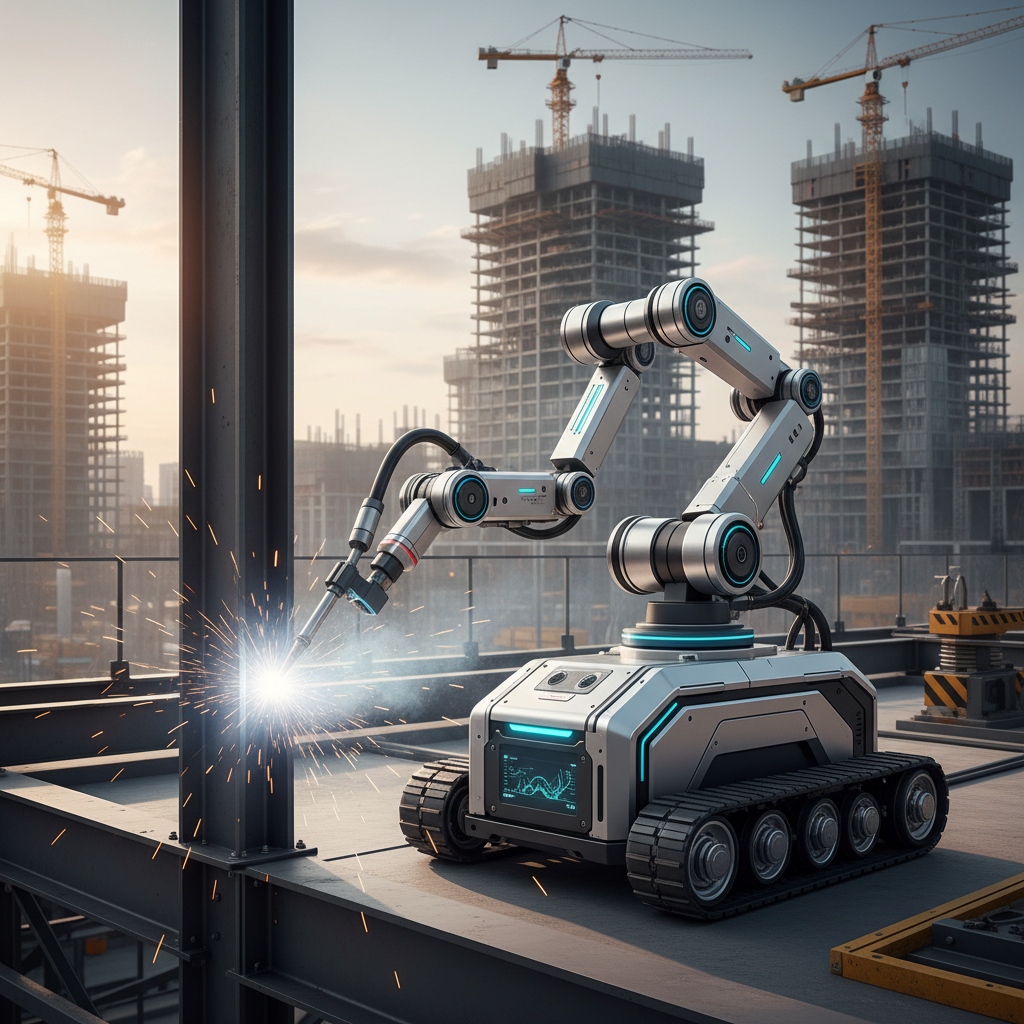

In the ever-evolving landscape of manufacturing and construction, the demand for efficiency and precision continues to rise, making the adoption of advanced technologies a cornerstone for success. One such innovation is the mobile welding robot, which offers flexibility and speed, significantly enhancing productivity in various applications. As businesses prepare to invest in these sophisticated machines, understanding how to choose the best mobile welding robot becomes essential to stay competitive in 2025.

This article will explore the top five considerations for selecting the most suitable mobile welding robot that aligns with your specific operational needs. From analyzing the technical features to evaluating the return on investment, we’ll provide insights that will aid decision-makers in making informed choices. By focusing on factors such as portability, user compatibility, and maintenance requirements, businesses can streamline their operations and elevate their welding capabilities to new heights. Whether you’re a small workshop or a large-scale manufacturing firm, choosing the right mobile welding robot will not only boost your productivity but also ensure high-quality output for your projects.

When selecting a mobile welding robot for your business in 2025, there are several key considerations that can significantly impact your operations. First, it's essential to assess the specific welding tasks you will be performing. Different applications, such as MIG, TIG, or arc welding, have unique requirements that may determine the type of robot best suited for your needs. Look for robots that offer versatility and can handle various materials and thicknesses.

Tip: Evaluate the robot’s payload capacity and reach to ensure it can manage the specific components you intend to weld. A robot with a higher payload can handle larger parts, while sufficient reach is crucial for accessing hard-to-reach areas.

Another critical factor is the software capabilities of the mobile welding robot. Efficient programming and ease of integration with existing systems can save time and enhance productivity. Review the user interface and consider robots that offer advanced features such as real-time monitoring, predictive maintenance, and compatibility with robotics simulation software.

Tip: Opt for a model that provides robust training and support resources, as this will help your team quickly adapt to the new technology and maximize its potential in your workflow.

When selecting the best mobile welding robot for your business in 2025, technical specifications play a crucial role in ensuring optimal performance and efficiency. Key factors to consider include the robot’s payload capacity, reach, and speed. A higher payload capacity allows the robot to handle larger welding tools and materials, while an extended reach enables it to work on a wider array of projects without repositioning. Speed is equally important; faster welding can significantly reduce production times, enhancing overall productivity.

Another critical specification is the type of welding process supported by the robot. For example, some robots are designed for MIG or TIG welding, which may be necessary depending on the materials you frequently work with. Additionally, examine the robot's software capabilities – aspects such as ease of programming and integration with existing systems can affect not just initial setup but also ongoing maintenance and operation. Robots equipped with advanced sensors and AI capabilities can adapt to different welding conditions in real-time, further improving welding quality and consistency. Adopting a thorough approach to evaluating these technical specifications will help ensure that you choose a welding robot that fits your business needs effectively.

When selecting a mobile welding robot for your business in 2025, understanding the balance between cost and value is paramount. Recent industry studies indicate that while the upfront cost of state-of-the-art mobile welding robots can range from $50,000 to $100,000, the value derived from enhanced efficiency and reduced labor costs can far outweigh these initial investments. According to a report by the International Federation of Robotics, automated welding technology has improved production speed by up to 40% and enhanced precision by nearly 30%, making it a crucial asset for modern manufacturing.

Furthermore, it's essential to consider the total cost of ownership (TCO) when evaluating mobile welding solutions. TCO encompasses not just the purchase price but also maintenance, energy consumption, and the potential for downtime. A study from the Welding Industry Association projects that companies that invest in automated solutions can expect a return on investment (ROI) of approximately 150% within the first three years of operation. This statistic highlights how investing in quality mobile welding robots can translate into long-term financial benefits, ultimately simplifying the decision-making process for businesses looking to modernize their welding capabilities.

When selecting a mobile welding robot for your business in 2025, understanding the importance of flexibility and versatility in welding robotics is paramount. The welding industry is witnessing a surge in demand for adaptable solutions due to increasingly complex manufacturing processes and varying project requirements. According to a report by MarketsandMarkets, the global robotic welding market is expected to grow from $4.82 billion in 2020 to $8.76 billion by 2025, driven by technological advancements and the need for efficient, customizable production.

Mobile welding robots that offer versatility enable businesses to easily switch between different applications, from automotive to industrial components. This adaptability not only streamlines operations but also significantly reduces downtime, which can lead to improved overall productivity. A study by the International Federation of Robotics (IFR) noted that companies utilizing versatile welding robots reported a 30% increase in operational efficiency, highlighting the critical role flexibility plays in modern manufacturing environments. As the competitive landscape evolves, investing in a mobile welding robot that can easily adapt to various tasks will be essential for businesses aiming to stay ahead.

As the welding robotics market continues to evolve, several brands are emerging as leaders in mobile welding technology for businesses in 2025. Companies like ABB, KUKA, and Fanuc are at the forefront, offering advanced models that cater to various industry needs. These brands have engineered solutions that combine speed, precision, and flexibility, making them ideal for diverse welding applications. The introduction of AI and machine learning in these robots enhances their capability to adapt to different materials and welding techniques, ensuring high-quality results.

While considering the best mobile welding robots, it’s crucial to examine specific models that stand out in 2025. The ABB IRB 6700 series offers excellent payload capacity and reach, making it suitable for heavier tasks. KUKA's KR AGILUS series boasts exceptional agility and compactness, perfect for tight working spaces. Additionally, Fanuc's ARC Mate 100iD model provides unrivaled precision and efficiency for arc welding operations. Evaluating these top brands and models will ensure businesses invest in the right technology to boost productivity and maintain competitiveness in the welding industry.