Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

In 2025, choosing the right automated welding solutions is crucial for your business success. The manufacturing landscape is evolving rapidly. Companies must adapt to stay competitive. As technology advances, so do the options available for automated welding. By understanding your specific needs, you can select the best equipment tailored to your operations.

Automated welding solutions can enhance productivity, reduce costs, and improve safety. However, it’s vital to assess your production volume and material types first. Some might discover that a complex system doesn’t fit their needs. Simplicity can sometimes yield better results. Additionally, investing in training for your team should not be overlooked.

Reflect on your current processes. Are they efficient? What challenges do you face? Thinking critically about these questions can guide you towards the right automated welding solutions. Remember, the most expensive option might not be the best fit. Focus on what truly enhances your business operations and growth.

As we look toward 2025, automated welding technologies are evolving rapidly. Businesses must understand these innovations to remain competitive. Robotic welding arms are becoming more accessible. They offer precision and speed, reducing errors in the welding process. Many companies appreciate how these machines enhance productivity. However, adaptation to this technology can pose challenges.

Another key development is the integration of artificial intelligence. AI systems optimize welding parameters in real-time. This can lead to better weld quality and reduced waste. Yet, businesses may encounter difficulties when training staff to use these advanced systems effectively. Human expertise remains crucial to troubleshoot problems during operation.

Moreover, advanced sensors are now integral to automated welding. These sensors monitor temperature and material quality continuously. Such real-time data collection can improve decision-making. Nevertheless, firms must invest in proper maintenance and upgrades. Ignoring this can lead to costly downtimes. Embracing these technologies requires careful planning and ongoing evaluation.

Choosing the right automated welding solutions is crucial for your business. Consider the specific needs of your operations. What materials will you weld? Is it steel, aluminum, or something else? Each material requires different techniques and settings. This can impact your final product.

Think about the scale of your production. Are you a small workshop or a large manufacturer? Smaller setups may benefit from flexible, compact systems. Larger operations should consider multi-functional machines that can handle various tasks. Efficiency is key. But be cautious; an overly complex system may not be the best choice.

Don't overlook the importance of compatibility. Ensure new machines integrate well with your existing equipment. This helps streamline processes. Training is another factor. Will your team adapt quickly? Some systems are user-friendly; others may require extensive training. Reflect on your team's skill set before making a decision. Balancing these factors can lead to more informed choices.

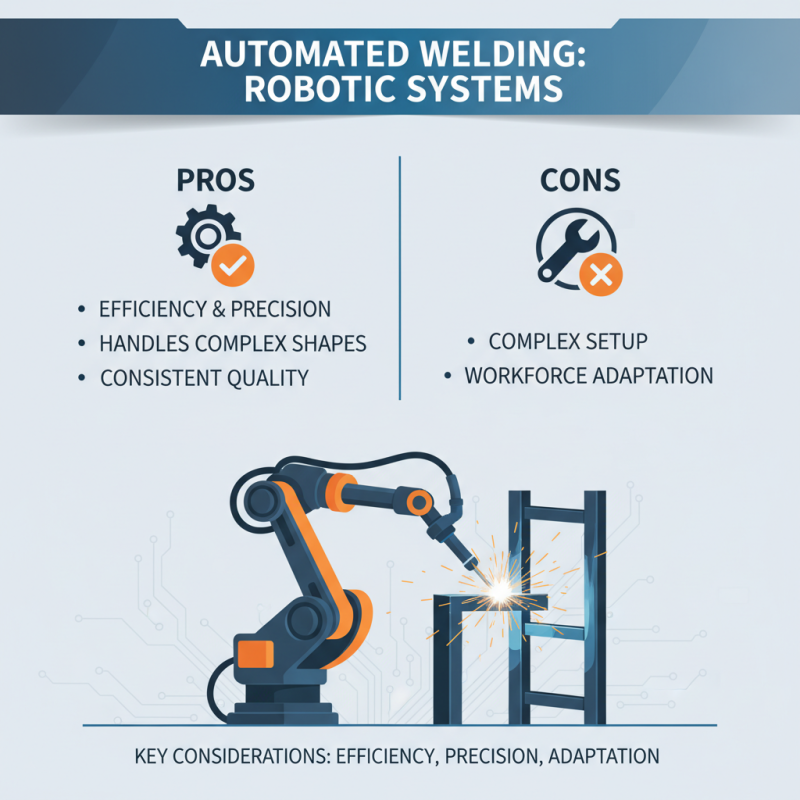

When selecting automated welding equipment, it's vital to compare different types. Robotic welding systems are popular due to their efficiency and precision. They can handle complex shapes with ease, but initial setup can be challenging and time-consuming. Ensure your workforce can adapt to this technology.

Another option is laser welding machines. These devices offer high-speed welding with minimal heat affected zones. However, they may require specialized training to master. The cost of maintenance can also be a concern for some businesses. Consider these factors carefully before deciding.

MIG and TIG welding automation are other routes to consider. MIG welding is faster and more forgiving, making it great for production. TIG welding, while slower, delivers superior welds for thin materials. Each method has its strengths and weaknesses. Weighing these will help you make an informed choice for 2025.

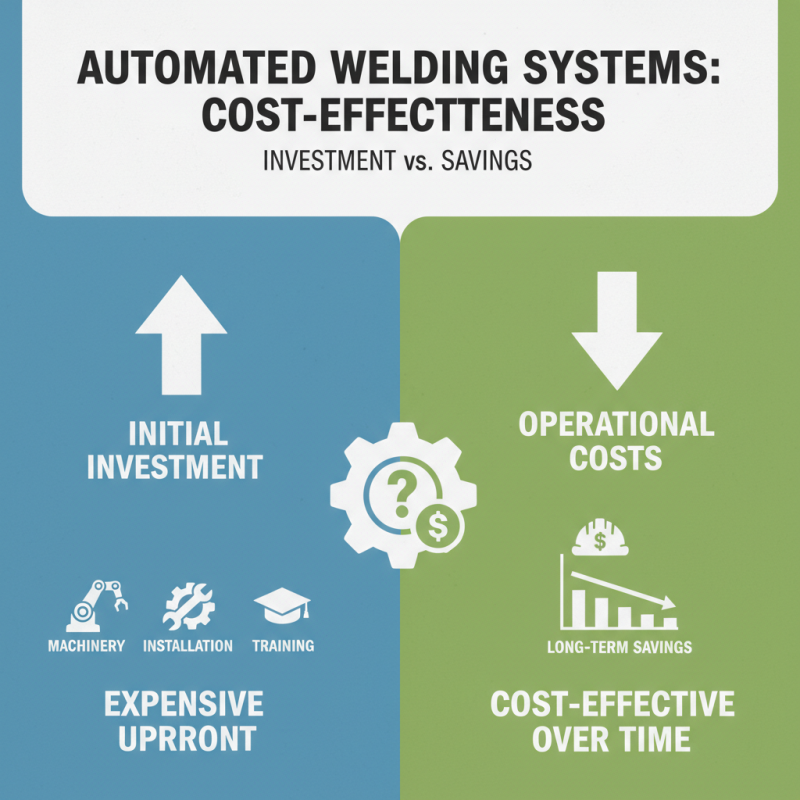

When evaluating the cost-effectiveness of automated welding systems, it's crucial to calculate initial investment and operational costs. Start by assessing the machinery costs, installation fees, and training. Automated systems can be expensive upfront. However, they often reduce labor costs in the long run. This is a significant factor that companies should not overlook.

Next, analyze the ROI. It helps to project potential savings from increased productivity and reduced errors. Automated welding can enhance precision and speed. Still, reflect on possible downtime and maintenance costs. These can affect the overall return. Are you prepared to manage these unexpected issues?

Lastly, consider the impact on workforce dynamics. While automation can streamline processes, it may lead to workforce reductions. This change can be difficult. Training employees to adapt to new technologies is vital. Ensure that the transition is manageable for everyone involved. Balancing automation benefits and workforce needs requires careful thought.

In 2025, automated welding will evolve significantly. Industries are moving towards increased efficiency and reduced labor costs. This shift introduces new technologies, such as artificial intelligence and advanced robotics. These innovations promise to enhance precision and speed in welding processes. However, integrating these technologies may not be seamless for every business.

Companies need to consider their specific needs. The transition can be overwhelming. Smaller firms might struggle to adapt, facing high initial costs. Training employees to use new systems adds another layer of complexity. Not every business will find immediate benefits. Metrics for success should be established early on. Balancing automation with human oversight is critical.

Future trends also highlight the importance of sustainability. Automated systems can reduce waste and energy consumption. However, companies must ensure that their choices are environmentally conscious. The move to automation must include reflections on social responsibility. It’s essential to prioritize ethical considerations while seeking technological advancements. The landscape of automated welding will undoubtedly require ongoing evaluation and adaptation.

| Feature | Description | Advantages | Considerations |

|---|---|---|---|

| Robotic Welding Arms | Advanced robotic arms designed for precision welding tasks. | High efficiency, consistent quality, and reduced labor costs. | High initial investment and complexity in integration. |

| Intelligent Control Systems | AI-driven systems that optimize welding parameters in real-time. | Enhanced adaptability and decreased defect rates. | Requires continuous data input and monitoring. |

| Mobile Welding Units | Easily transportable welding equipment for on-site operations. | Flexibility and the ability to respond quickly to job demands. | Potential limitations on power supply and equipment capacity. |

| 3D Printing Integration | Welding systems that incorporate 3D printing capabilities. | Innovative designs and rapid prototyping potential. | Technical challenges and material compatibility issues. |

| Safety Features | Automated systems equipped with safety protocols and sensors. | Reduced workplace accidents and enhanced operator safety. | Ongoing maintenance and troubleshooting required for systems. |