Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

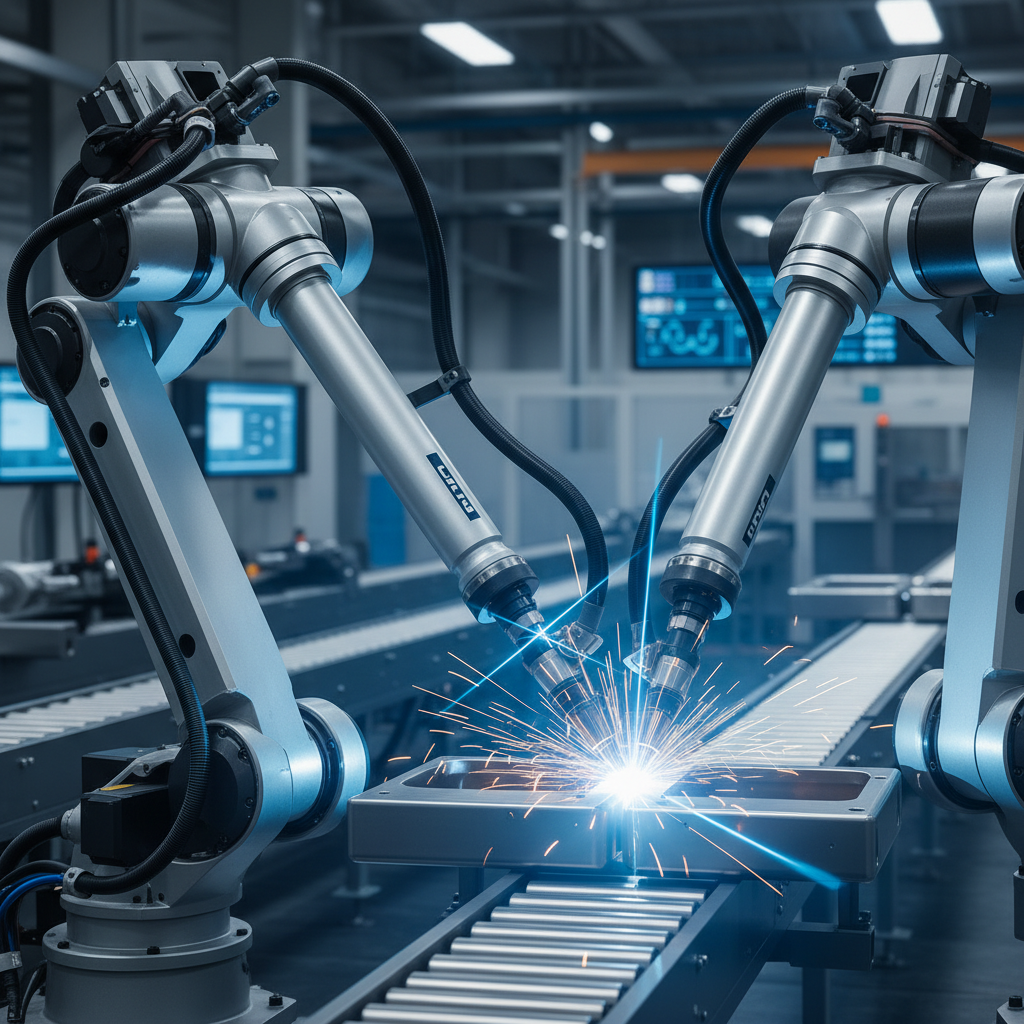

In the rapidly evolving landscape of manufacturing, the integration of automation has become paramount for operational efficiency and precision. Among the various automation solutions available, the OTC robot welder stands out for its cutting-edge technology and unparalleled performance. According to the International Federation of Robotics, the use of industrial robots has grown by an average of 15% annually, indicating a robust shift toward automated welding solutions. Such advancements enable manufacturers to enhance productivity while maintaining high-quality standards.

Expert insights further validate the growing trend towards utilizing OTC robot welders. Dr. Emily Carter, a renowned robotics specialist at the Robotics and Automation Institute, emphasizes the advantages of these systems: "The OTC robot welder not only boosts production rates but also significantly reduces the risk of human error, making it an ideal choice for modern manufacturing environments." As the industry pushes toward more automated processes, investing in an OTC robot welder is not just strategic but essential for companies aiming to stay competitive in the market.

In light of these factors, it is clear that selecting an OTC robot welder can deliver substantial benefits in terms of efficiency, quality, and cost savings. As we explore the "2025 Top 10" reasons to adopt this technology, it becomes evident that the future of welding will be dominated by such sophisticated robotic solutions, further solidifying the position of OTC in the manufacturing sector.

In modern manufacturing, the integration of OTC robot welders offers numerous advantages that streamline operations and enhance productivity. These advanced machines not only reduce the time and labor required for welding tasks but also ensure a greater degree of precision and consistency in weld quality. Manufacturers can greatly benefit from improved efficiency and reduced operational costs as these robots minimize human error and optimize workflow.

Tips for selecting the right OTC robot welder include assessing the specific needs of your manufacturing process, such as material types and production volume. Additionally, consider the ease of programming and integration with existing systems to maximize the return on investment. Regular training for operators is also essential to fully leverage the capabilities of the welding robots and ensure safety protocols are followed.

Moreover, investing in OTC robot welders can significantly enhance workplace safety. By automating dangerous welding tasks, manufacturers can protect their workforce from hazardous exposure, which is a critical aspect of modern industrial operations. This not only fosters a healthier work environment but also aligns with regulatory safety standards, ultimately contributing to the long-term success of manufacturing enterprises.

The cost-effectiveness of utilizing OTC robot welding technology is a compelling reason for manufacturers to consider this advanced solution. Industry reports indicate that companies implementing robotic welding can see up to a 25% reduction in labor costs, thanks to increased automation and efficiency. By minimizing human error and maximizing precision, OTC robot welders contribute to significantly lower production costs, ultimately driving higher profit margins for businesses. Additionally, these robots can operate continuously in high-demand environments, further enhancing productivity while reducing overtime expenses associated with manual labor.

Tip: To maximize your investment, ensure proper training for your staff on the operation and maintenance of robotic welders. This will help minimize downtime and keep your production line running smoothly.

Furthermore, OTC robots also lead to savings in material usage through their accurate welding capabilities. According to recent studies, the implementation of robotic solutions can decrease scrap rates by up to 30%. This optimization not only saves money on materials but also streamlines the overall manufacturing process, enabling quicker turnaround times without compromising quality.

Tip: Regularly review and analyze your welding processes to identify areas where robotic welding can be integrated or improved for better cost savings.

When it comes to manufacturing, precision and consistency are paramount. OTC robots are designed to enhance both, making them an ideal choice for businesses looking to elevate their production processes. These advanced robotic welders leverage state-of-the-art technology to ensure that every weld is executed with pinpoint accuracy. This level of detail minimizes errors, reduces the need for rework, and ultimately leads to higher quality products.

In addition to precision, OTC robotics also excels in maintaining consistency across large-scale manufacturing operations. Once programmed, these robots can reproduce the same welding procedure repeatedly without fluctuations in quality. This reliability not only streamlines production but also supports compliance with stringent industry standards. By integrating OTC robots into your manufacturing workflow, you can achieve a level of uniformity that manual processes simply cannot match. This positions your business to meet increasing demands while maintaining the excellence that your customers expect.

When it comes to selecting a welding solution for manufacturing, OTC robot welders stand out for their flexibility and adaptability. These robots can be programmed and reconfigured to handle various welding tasks, making them ideal for projects of different scales and complexities. Whether you’re working on automotive parts, structural components, or intricate fabrications, OTC robot welders can adjust to your specific requirements, ensuring high precision and consistency across all applications.

Tip: When integrating an OTC robot welder, consider investing in training for your operators. A well-trained team can maximize the robot’s capabilities, leading to better efficiency and reduced downtime.

Another significant advantage of OTC robot welders is their ability to work in diverse environments and with various materials. They are designed to seamlessly switch between materials like aluminum, steel, and even plastic, making them a versatile choice for manufacturers looking to diversify their product offerings. This adaptability not only streamlines the production process but also allows for quick responses to market demands.

Tip: Use simulation software to design your welding processes before implementation. This can help identify the best setups and configurations for your specific projects, ultimately saving time and resources.

In today’s manufacturing landscape, safety and efficiency are paramount concerns. Choosing an OTC robot welder can significantly enhance the safety of your operations. These advanced welding solutions not only improve precision and consistency but also reduce the potential for accidents that can arise from manual welding processes. By automating the welding tasks, manufacturers can minimize human error and create a safer work environment.

**Tips for Implementing OTC Welding Solutions:**

1. **Training**: Ensure your team is well-trained in both operating and maintaining automated welding machines. Proper training can prevent misuse and enhance safety.

2. **Regular Maintenance**: Schedule routine checks and maintenance for your welding robots to ensure they operate smoothly and safely.

3. **Workstation Ergonomics**: Design your robotics workstation to optimize workflow and minimize the risk of injury, making sure operators have easy access to essential controls without straining.

Investing in OTC welding solutions not only helps in mitigating labor risks but also creates a more productive workspace. Manufacturers will find that the integration of these robotic welders is a pivotal step towards achieving both safety and efficiency in their operations.