Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

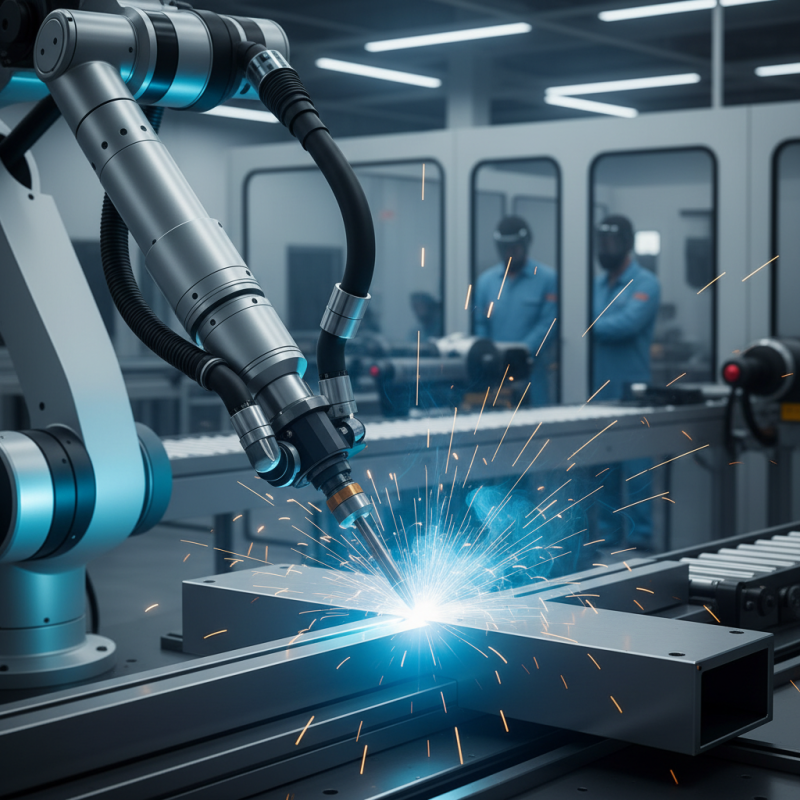

TIG robotic welding has transformed the manufacturing landscape. It combines precision and efficiency, making it a top choice for many industries. This method uses tungsten electrode and inert gas, providing a clean weld.

Implementing effective TIG robotic welding techniques can boost productivity. However, challenges persist. Machines may require frequent calibration. Moreover, skilled operators are essential for programming and maintenance.

Exploring the best practices in TIG robotic welding can reveal areas for improvement. Identifying common pitfalls, like inconsistent feed rates, can enhance output quality. Adopting adjustments based on real-world applications may increase operational efficiency. The journey is ongoing as industries strive for perfection.

TIG robotic welding is an advanced technique that enhances welding precision and speed. Understanding the fundamentals is crucial for maximizing efficiency. This method uses a non-consumable tungsten electrode and an inert gas, usually argon, to protect the molten weld pool. It allows for clean and strong welds, making it popular in various industries.

Tips: Ensure the workpiece is clean. Contaminants can lead to poor welds. Take time to prepare surfaces before welding. Sometimes, the robot may not follow the path perfectly. Program adjustments might be needed for better outcomes.

Understanding heat input is essential. Higher heat may lead to warping or burn-through. Monitor the settings closely. Adjust the voltage and travel speed based on material thickness. It can take time to find the right balance.

Tips: Always conduct test welds. They help identify issues early. This practice can save time and materials later. Regular maintenance on the robot will keep it running smoothly. Pay attention to wear and tear for consistent performance.

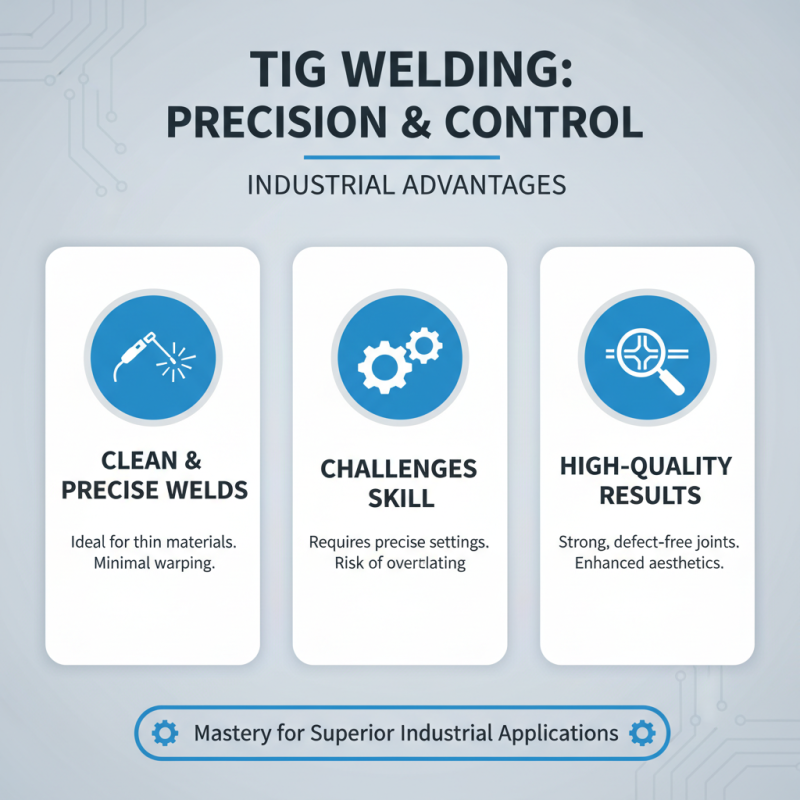

TIG welding, or tungsten inert gas welding, offers significant advantages in industrial applications. One key benefit is its ability to produce clean and precise welds. This technique is ideal for thin materials. It minimizes the risk of warping, a common issue in other welding methods. However, achieving the perfect balance in settings can be challenging. Inexperienced welders might overheat the material, leading to defects.

Another important advantage is the versatility of TIG welding. It can be used on various metals, including stainless steel and aluminum. This flexibility allows for diverse applications across industries. Yet, the learning curve is steep for some. Mastering the technique requires practice and patience. Beginners often struggle with torch control and filler rod manipulation. These challenges can be discouraging but are essential to overcome for desired results.

Efficiency is another critical aspect. TIG welding can produce high-quality results in less time. However, it demands concentration and skill. Workers must stay focused to maintain consistency. A lapse in attention can lead to mistakes and wasted materials. Tips for improved efficiency include regular practice and maintaining equipment. Proper preparation can also make a difference, ensuring that the workspace is orderly and ready for use.

TIG welding offers excellent precision and control. However, optimizing its performance can be challenging. According to industry reports, a significant portion of weld defects stems from inadequate technique. Utilizing the right approach can lead to a 30% boost in efficiency.

The key to optimizing TIG welding lies in proper preparation and settings. Tungsten electrode preparation is crucial. A clean, sharp point aids in arc stability. Reports indicate that a properly sharpened tungsten reduces spatter by 25%. Additionally, using the right filler material ensures strong joints and minimizes rework. The importance of maintaining a consistent travel speed cannot be overstated. Variations can lead to defects or weak seams.

Another essential factor is heat control. Overheating can cause burn-through. Yet, underheating may lead to incomplete penetration. Finding the balance is tricky but vital. Implementing pulse welding techniques can help manage heat input. These methods allow for better control over the weld pool. They can also reduce distortion by using less heat overall. Industry observations suggest that effective heat management can improve weld quality by up to 40%.

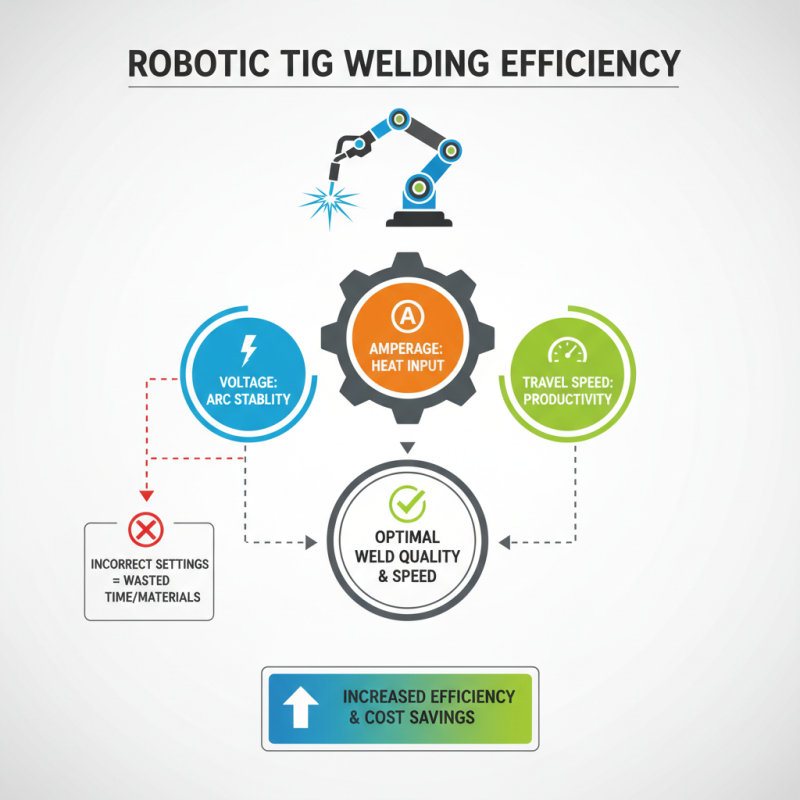

When it comes to robotic TIG welding, efficiency hinges on various factors. The setup of the welding parameters plays a pivotal role. Proper voltage, amperage, and travel speed directly impact weld quality and productivity. If these settings are incorrect, the process can become inefficient, leading to wasted time and materials.

Tips: Regularly check and adjust your welding parameters. Too high or low settings can cause defects. Keep records of successful settings for future use.

Another key factor is the robot's programming. Simple paths can improve speed but may compromise quality. On the other hand, complex movements can enhance precision but slow the process down. This balance is crucial for efficiency.

Tips: Test your robot on different paths. Observe which provide the best quality without sacrificing speed. This exploration can reveal hidden efficiencies.

Material preparation also matters. Clean surfaces promote better weld penetration and reduce the need for rework. Ignoring this step can lead to more failures and downtime. Regular inspections of materials can save time in the long run.

Maintaining TIG systems is crucial for operational efficiency. Regular checks on the gas flow rate can prevent welding defects. Ideally, the flow rate should be around 15-20 CFH for most applications. Inconsistent flow can lead to issues like contamination or improper shielding. Monitoring this factor ensures better weld quality.

Troubleshooting is a common necessity in TIG welding. Inspect the torch regularly for damage or wear. A damaged tungsten electrode can create arc stability problems. Reports suggest that 30% of welding defects stem from improper electrode preparation. Checking dimensions can significantly impact performance.

Periodic cleaning of components is also vital. A clean workspace minimizes debris in the welding area. In fact, nearly 25% of weld failures are linked to surface contamination. Keeping equipment and surfaces clean improves overall reliability. Engage in regular training to understand newer techniques and identify issues quickly. Continuous learning is key to enhancing TIG welding functionality.