Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

In recent years, the robotics sector has seen substantial advancements in manufacturing processes. The demand for robotic welding machines has surged, driven by their efficiency and precision. According to a report by Markets and Markets, the global robotic welding market is expected to reach $5.5 billion by 2026, showing a CAGR of 7.4%. This growth highlights the integral role robotic technology plays in modern manufacturing.

Experts in this field, like Dr. Emily Chen, believe that "the future of welding lies in automation." Her insights underscore the trend towards adopting robotic welding machines. These machines not only promise reduced labor costs but also enhance the consistency of weld quality. Additionally, industries are increasingly recognizing the potential of integrating AI to improve welding processes.

However, the excitement about innovations does not overshadow existing challenges. As companies rush to implement robotic systems, many face integration issues. In addition, worker retraining remains a significant barrier. The evolution of robotic welding machines is indeed promising, but it also prompts reflection on the skills gap and the need for a balanced approach to automation.

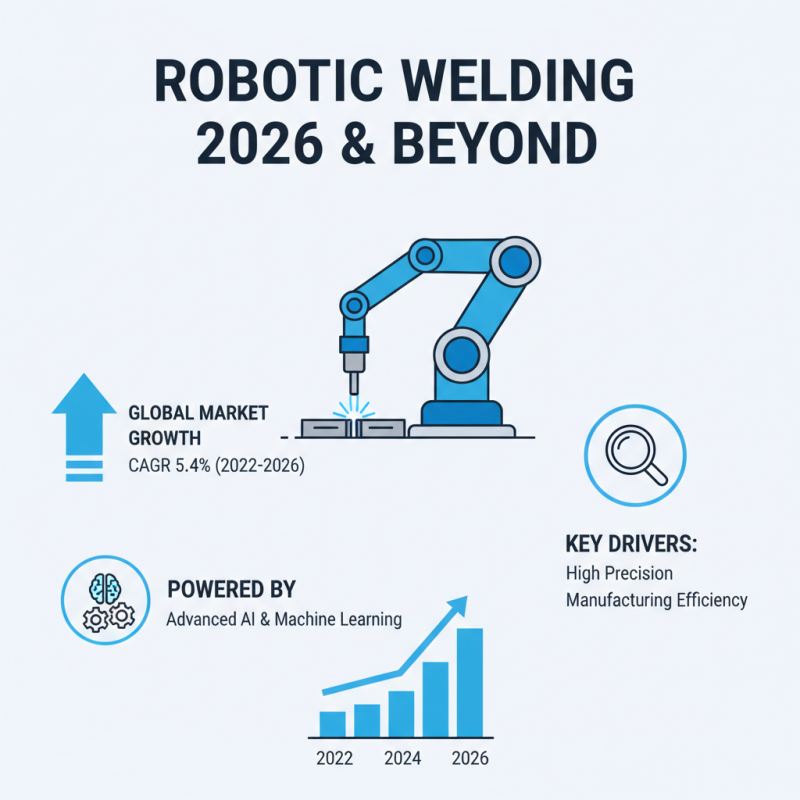

As we look ahead to 2026, robotic welding technology is poised for a transformative leap. Emerging technologies, such as advanced AI and machine learning, are driving these changes. According to a recent industry report, the global market for robotic welding is projected to grow at a CAGR of 5.4% through 2026. This growth is fueled by the demand for high precision and efficiency in manufacturing processes.

Adaptive learning is a significant trend that will shape robotic welding. Weld robots can now adjust parameters in real-time. This allows for improved performance in variable conditions. Imagining a system that learns from each welding session shows promise. However, not all systems are fully capable of integration. Over-reliance on technology may lead to unexpected faults in operation.

Another critical aspect is the rise of collaborative robots, or cobots. They work alongside human workers, enhancing safety and productivity. A recent survey indicates that 53% of manufacturers are exploring cobot integration. Yet, the challenge remains in establishing clear boundaries. Ensuring safety while maximizing productivity can be difficult. The journey to perfect synergy between humans and robots is still ongoing.

As the welding industry evolves, AI and machine learning are changing automation. Data from a recent industry report shows that smart welding machines boost efficiency by up to 25%. This technology helps identify errors in real-time, leading to less rework. Precision is crucial in welding, and these advancements ensure improved quality control.

Integration of machine learning algorithms enhances decision-making capabilities. They analyze historical data to predict welding defects before they happen. This predictive capability reduces downtime and waste. It's impressive that some systems can learn from each weld, improving with every project. However, reliance on technology raises questions about skill gaps in the workforce.

Despite these advancements, challenges remain. Many facilities struggle to fully implement AI solutions. There’s a steep learning curve, and not all teams are ready. Trusting machines to make decisions can be daunting. Continuous training is essential to bridge the knowledge gap. Adopting smart welding requires investment in time and resources, which may not yield immediate results. These factors must be considered carefully as the industry moves forward.

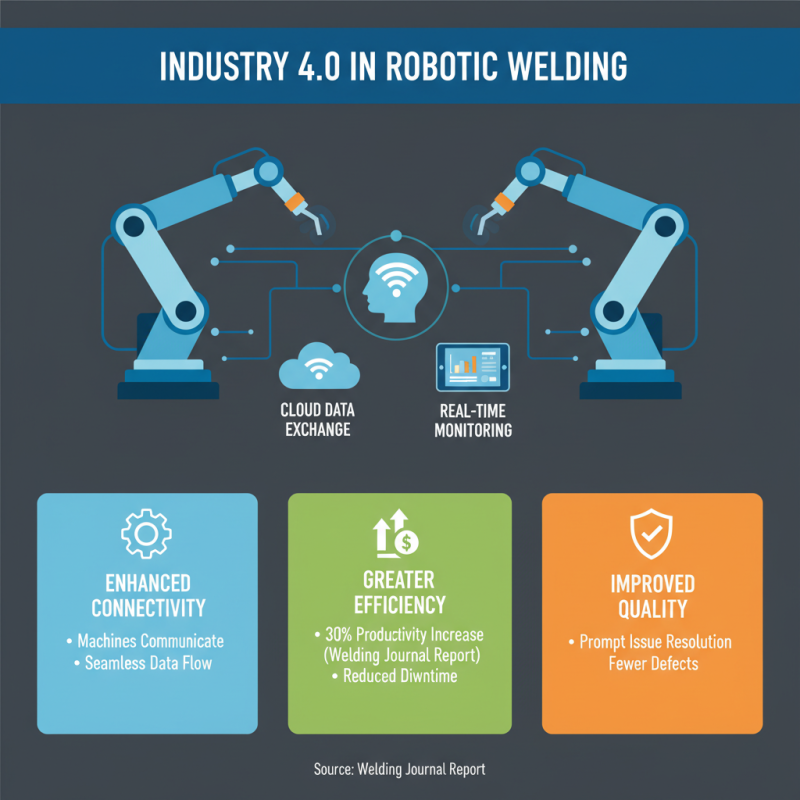

The integration of Industry 4.0 in robotic welding is transformative. It enhances connectivity and data exchange between machines, leading to greater efficiency. According to a recent report by *Welding Journal*, companies using advanced automation saw a 30% productivity increase. Real-time data monitoring allows welders to address issues promptly, reducing defects.

However, this technology isn't without challenges. Many operators struggle with the rapid pace of change. Not all staff are equipped with the necessary skills to adapt. A survey by *Factory Equipment* revealed that 40% of manufacturers cited skill gaps as a major barrier to full implementation. Additionally, the high initial investment can deter smaller firms from adopting these innovations.

Robotic welding systems are evolving. They now feature adaptive learning capabilities powered by AI. This innovation helps in fine-tuning processes continuously. Yet, these systems can sometimes misinterpret data, leading to unexpected outcomes. Industries must remain vigilant. They must balance automation with the human touch, ensuring quality and safety are never compromised.

The rise of robotic welding is closely tied to sustainable practices. These innovations focus on reducing waste and conserving energy. Companies are prioritizing eco-friendly materials and processes. This shift not only helps the environment but also cuts costs.

Using energy-efficient robots can significantly reduce electricity consumption. Integrating sensors allows for real-time monitoring, which minimizes errors. However, the initial investment may deter some businesses. Consider this carefully, as the long-term savings can be substantial.

Tips: Invest in training programs. Well-trained staff can optimize operations. Additionally, evaluate your supply chain. Using local materials can further reduce your carbon footprint. Reflect on your current practices and identify areas for improvement. Sustainability is not just a trend; it's becoming a necessity in manufacturing.

The shift towards robotic welding systems is gaining traction, yet challenges remain. Many manufacturers fear high initial investment costs. This concern often stifles innovation and limits growth. The perception that robotic systems require extensive programming skills adds to the reluctance. In some cases, companies hesitate to transition due to a lack of skilled labor.

Integrating these systems into existing workflows can be complex. Training staff on new equipment is critical yet often overlooked. Some employees may resist change, preferring traditional methods. This creates a gap between the potential benefits and actual implementation. Additionally, maintenance of robotic systems requires a different skill set, leading to further complications.

Addressing these challenges requires proactive strategies. Offering comprehensive training programs can ease the transition. Engaging employees in the change process may also foster acceptance. Continuous evaluation of the systems' performance will highlight areas for improvement. Open conversations about challenges should be held regularly, creating a feedback loop. This approach can build a culture of adaptation and innovation, crucial for success in robotic welding.

| Trend / Innovation | Description | Challenges | Solutions |

|---|---|---|---|

| AI Integration | Utilization of artificial intelligence to enhance precision and efficiency. | High implementation costs, need for skilled personnel. | Invest in training programs and phased rollouts. |

| Cobots Collaboration | Collaborative robots working alongside human welders for enhanced safety. | Regulatory compliance and safety concerns. | Develop stringent safety protocols and training workshops. |

| Remote Monitoring | Real-time monitoring of welding processes using IoT devices. | Data security issues and integration challenges. | Use encryption and invest in compatible software solutions. |

| Increased Mobility | Robotic systems designed for flexibility and mobility across various workspaces. | Potential stability issues and adaptability to different environments. | Focus on design that enhances stability and adaptability. |

| Enhanced Safety Features | Incorporation of advanced safety technologies to protect workers. | Cost of technology and training on new systems. | Gradual integration and demonstrating ROI through safety improvements. |