Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

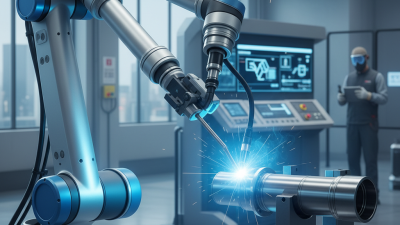

The world of robotic welding machines is evolving rapidly. Industry expert Dr. Emily Zhao emphasizes, “Innovation in robotic welding will shape the future of manufacturing.” As industries push for efficiency, these machines play a pivotal role. They reduce human error and increase productivity.

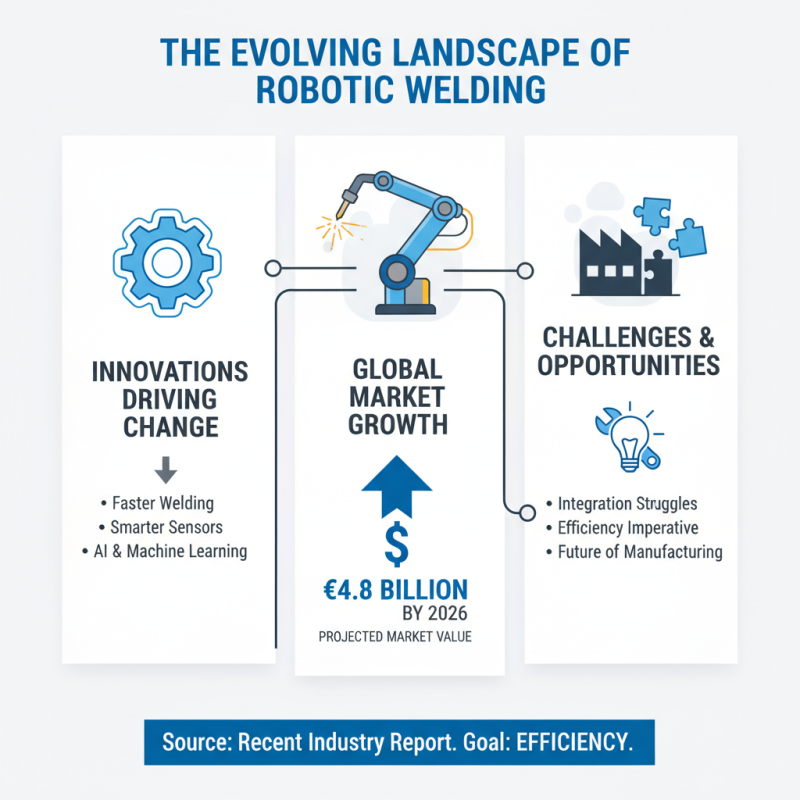

However, the journey is not without challenges. Many businesses struggle to adapt to new technologies. Not every company can afford the latest models. Moreover, the need for skilled operators remains critical. While robotic welding machines can enhance production, they also demand a trained workforce.

As we look toward 2026, it's clear that innovation will continue. Trends in automation and AI integration could redefine the welding landscape. The potential for growth is immense, yet careful consideration is needed. Balancing technology with the human element will be essential for success.

As industries evolve, robotic welding is embracing new technologies for 2026. One trend is the integration of AI-driven systems. These systems improve accuracy and efficiency. According to a recent industry report, deploying AI can reduce production errors by up to 30%. More precise welding ensures a higher quality product.

Emerging technologies also include the use of advanced sensors. These sensors can detect anomalies in real-time. A study highlights that this type of monitoring can enhance operational uptime by approximately 25%. However, there are challenges. High initial costs and the need for skilled technicians can complicate implementation.

Automation remains at the forefront. Companies are investing in collaborative robots, or cobots, to assist workers. Collaborative systems can boost overall productivity by around 20%. Yet, the transition isn’t always smooth. Organizations must ensure proper training and risk assessments to mitigate potential issues. Balancing innovation with practical application is essential.

This chart displays the projected trends in robotic welding technologies for 2026, focusing on various innovations and their expected market share.

The landscape of robotic welding machines is rapidly evolving. Innovations are shaping the future of industries. Based on a recent report, the global robotic welding market is projected to reach $4.8 billion by 2026. Efficiency is the goal, yet many facilities still struggle to fully integrate these technologies.

One significant trend is the rise of artificial intelligence in welding machines. AI enhances decision-making in real-time, improving accuracy. Reports show that AI can cut weld defects by 30%. However, implementing AI can be challenging. Industry professionals must upskill their teams to manage these advanced systems effectively.

Another innovation is the use of 3D modeling software. This tool allows for precise welding paths, reducing material wastage. A study indicated that companies using this technology can increase productivity by 25%. But, many still face a steep learning curve. Inconsistent training can lead to mistakes, often resulting in rework and delays. Balancing innovation with practical application remains a critical challenge in adopting these technologies.

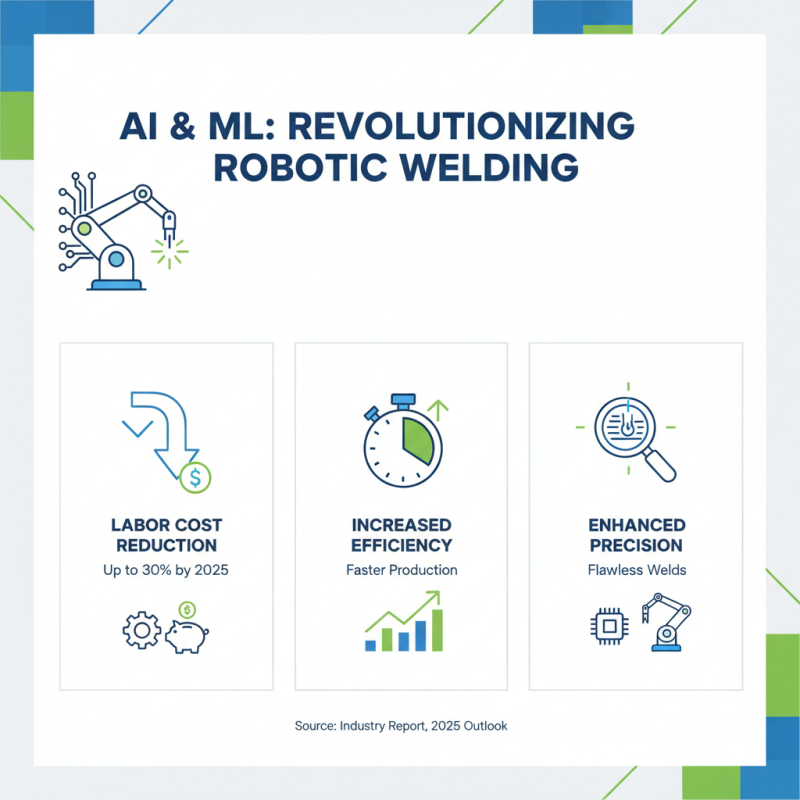

The integration of AI and machine learning is transforming robotic welding systems. According to a recent industry report, by 2025, AI-enabled automation could reduce labor costs by up to 30%. This could lead to increased efficiency in production processes. Industries are gradually adopting these technologies to enhance precision in welding tasks.

Machine learning algorithms can analyze vast amounts of data in real time. This allows machines to learn from previous welds, improving quality over time. It's reported that these advancements can minimize defects by as much as 25%. However, reliance on algorithms poses risks. It’s essential for companies to maintain a balance between automation and human oversight.

Despite these advancements, challenges remain. Some welding tasks still require human intervention for complex designs. The initial costs of implementing AI can be high, which may deter smaller enterprises. Thus, while the potential is great, assessment and adaptation are crucial for success in robotic welding.

As industries embrace automation, robotic welding is evolving. Safety and ergonomics are critical factors for successful implementation. In 2026, the focus will shift towards enhancing worker safety. Recent studies reveal that ergonomic risks are prevalent in robotic welding operations. A significant 70% of accidents arise from improper setups or operator fatigue.

Tips: Regular training sessions can help. Ensure operators understand how to position themselves safely around machines. This reduces fatigue and enhances productivity.

Moreover, advances in safety technology are crucial. Innovations like collision detection systems are becoming standard. These systems help prevent workplace injuries. Significant data indicates a potential 40% reduction in accidents with improved safety measures. However, integrating new systems can be challenging. Companies must ensure proper implementation and training.

Tips: Conduct audits on existing safety protocols. Identify gaps and areas for improvement. Engaging employees in this process can foster a culture of safety.

| Trend | Description | Industry Impact | Safety Enhancements | Ergonomics Improvements |

|---|---|---|---|---|

| Increased Automation | Greater reliance on automated welding processes to improve efficiency. | Higher productivity rates across manufacturing sectors. | Minimized human exposure to hazardous environments. | Less physical strain on operators. |

| Smart Welding Technology | Integration of AI and machine learning to enhance welding parameters. | Improved quality control and defect detection. | Real-time monitoring to avoid accidents. | Augmented assistance tools for operators. |

| Collaboration with Robotics | Collaborative robots working alongside human welders. | Enhanced workflow and flexibility in production lines. | Reduced risk of workplace accidents. | Easier task management through shared responsibilities. |

| Advanced Materials | Innovative materials that are easier to weld and offer better performance. | Broader applications in various industries. | Safer practices with less volatile materials. | Improved handling and usability for workers. |

| Data-Driven Decision Making | Leveraging big data and analytics to optimize welding processes. | Informed decisions lead to operational efficiencies. | Greater awareness of safety metrics. | Designs that promote better posture and reduce fatigue. |

The robotic welding industry is poised for significant growth by 2026. According to recent reports, the global market for robotic welding solutions is expected to exceed $6 billion. This increase is largely driven by advancements in automation technology. Industries are embracing these innovations to enhance productivity and reduce labor costs. Many manufacturers are re-evaluating their welding processes for efficiency.

Despite this growth, challenges persist. The high initial investment in robotic systems can deter small and medium enterprises. Moreover, there is a skills gap in the workforce. Companies need skilled personnel to operate and maintain these advanced systems. Training programs are crucial for bridging this gap. Industry experts recommend investing in education and resources to ensure a knowledgeable workforce.

Additionally, the integration of AI and machine learning is reshaping the landscape. These technologies enable real-time monitoring and quality control. However, there is a potential risk of over-reliance on automation. Businesses must balance technology with human oversight. A mixed approach might yield the best outcomes in robotic welding processes. Keeping these elements in mind will be essential as the industry evolves.